Product Advantages

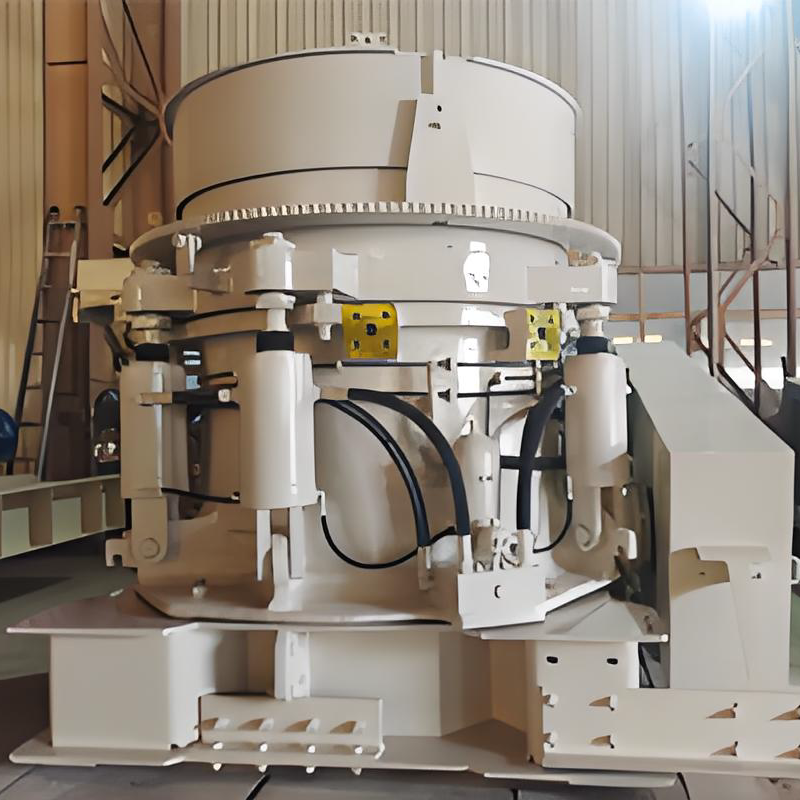

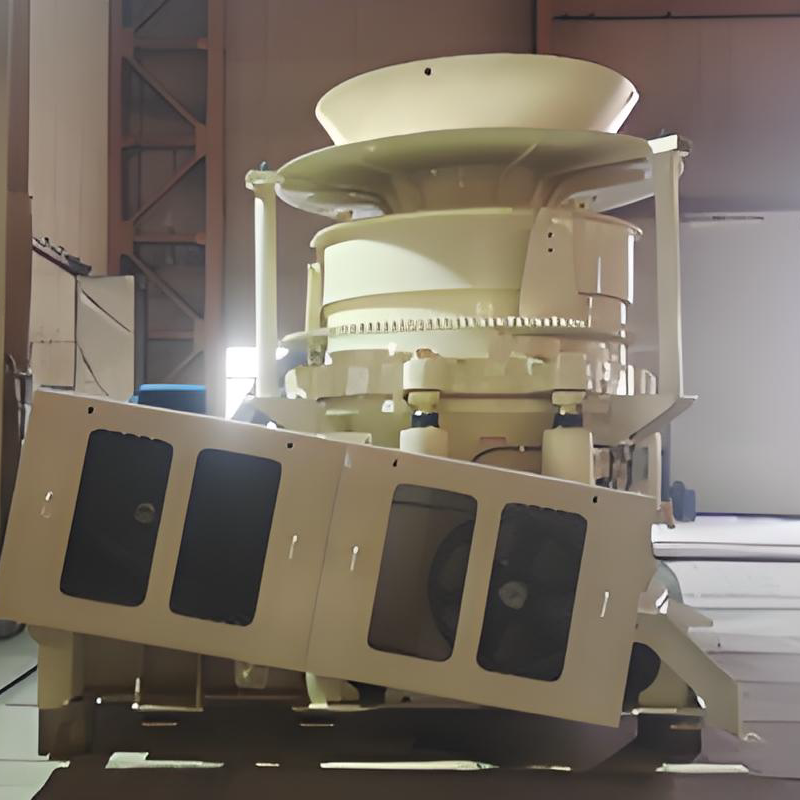

Equipment Introduction

The MHP Series Multi-Cylinder Hydraulic Cone Crusher elevates cone crusher performance to a new level. Compared with cone crushers of the same specifications on the market, it delivers the highest crushing power.

With a larger stroke, materials can easily enter the crushing chamber, maintaining continuous and stable crushing capacity throughout the full life cycle of the wear liners.

Material Range & Applications

Sand and gravel plants, concrete batching plants, dry mortar, power plant desulfurization, quartz sand, etc.

Metallic minerals such as iron, gold, copper; non-metallic materials such as river pebbles, granite, basalt, limestone, quartz, diabase, etc.

Equipment Reliability

The MHP Series Multi-Cylinder Hydraulic Cone Crusher performs excellently in various mining operations and is renowned for its cost-effectiveness and high crushing force.

Even when the crushing chamber liners are worn, it can avoid local blockage at the feed opening and maintain continuous and stable crushing.

Enhanced Automation

Equipped with an advanced PLC electrical system to continuously monitor operational status. It is simple to operate, safe, and reliable. The single-machine control system can also be integrated into a production line control system for coordinated control.

Hydraulic Protection & Thin Oil Lubrication

Hydraulic adjustment of the discharge opening, overload protection, and cavity cleaning allow uncrushable materials to pass through the crushing chamber instantly, maintaining high crushing force. After passing through, the crusher automatically restores the discharge opening to its preset size, reducing downtime and improving crushing efficiency. This greatly extends equipment service life.

Versatile & Easy Maintenance

The modular design of the MHP Series Cone Crusher allows for easy component replacement. Every detail in each module is carefully considered, with one-touch disassembly for convenient routine maintenance. This ensures safe and simple maintenance.

Parameters

Performance Parameters Table

Model | Chamber Type | Narrow Side Feed Opening (mm) | Minimum Discharge Setting (mm) | Capacity (t/h) | Motor Power (kW) |

MHP800 | Standard Coarse | 343 | 32 | 490–1930 | 630 |

Standard Medium | 308 | 25 |

Standard Fine | 241 | 19 |

Standard Extra Fine | 144 | 19 |

Short Head Coarse | 113 | 12 |

Short Head Medium | 71 | 10 |

Short Head Fine | 43 | 8 |

MHP1000 | Standard Coarse | 360 | 38 | 610–2420 | 750 |

Standard Medium | 343 | 32 |

Standard Fine | 242 | 25 |

Standard Extra Fine | 241 | 22 |

Short Head Coarse | 235 | 19 |

Short Head Medium | 140 | 12 |

Short Head Fine | 90 | 10 |

Short Head Extra Fine | 63 | 8 |

MHP1300 | Standard Coarse | 368 | 38 | 590–3020 | 1000 |

Standard Medium | 351 | 32 |

Standard Fine | 250 | 25 |

Standard Extra Fine | 249 | 22 |

Short Head Coarse | 148 | 12 |

Short Head Medium | 98 | 10 |

Short Head Fine | 71 | 8 |

FAQs

Q1: Are you a trading company or a manufacturer?

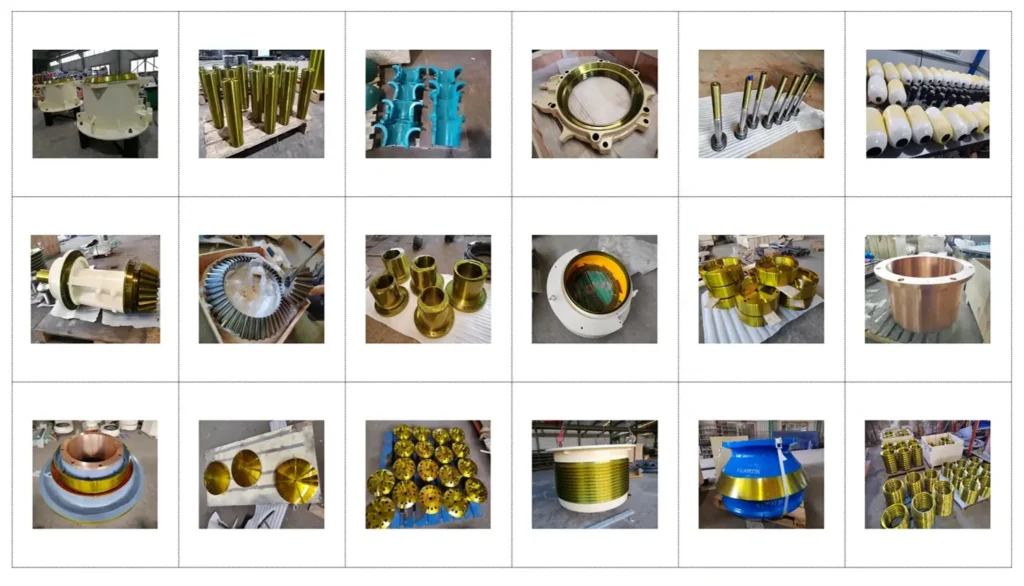

A: Metalore is a professional manufacturer. We specialize in crusher spare parts and metallurgical equipment. Our products are exported worldwide and trusted by customers in multiple countries. We focus on providing high-quality replacement parts for internationally renowned brands such as Metso, Sandvik, Terex, and offering reliable alternatives at competitive prices without compromising performance.

Q2: Do you accept customization?

A: Yes, we offer customization. You need to provide drawings or technical requirements, and our engineering team will produce according to your specifications. You can also provide the part numbers for the original equipment (Metso and Sandvik).

Q3: What are your service and payment terms?

A: We accept T/T and L/C. Standard terms are 30% deposit in advance, 70% balance before delivery, which is common in international trade. We will provide product photos for your confirmation before shipment to ensure accuracy and quality.

Q4: Do you provide technical support or installation guidance?

A: Yes, we offer professional technical support, including product selection guidance, installation instructions, and troubleshooting assistance.

Q5: Can Metalore products replace original brand parts directly?

A: Yes, our replacement parts are designed to be fully compatible with original brand equipment, offering reliable alternatives that meet or exceed OEM standards.

Q6: How do you ensure product quality?

A: Our products come with a one-year warranty and undergo physical and chemical testing before leaving the factory, including spectrometer analysis, flaw detection, hardness testing, and other relevant tests.