Product Name: Cone Crusher Adjustment Ring – Aftermarket Replacement

Material: High-strength alloy steel / Forged steel / Custom materials available upon request

Function:

The adjustment ring is a critical component of a cone crusher, installed at the top of the crusher to support the mantle and upper bearing assembly. It allows precise adjustment of the discharge opening, enabling control of the output particle size. The adjustment ring also stabilizes the mantle movement and protects the upper structure of the crusher, ensuring reliable and safe operation under high-load conditions.

Compatibility:

Compatible with a wide range of cone crushers from leading brands, including Metso, Sandvik, FLSmidth, Nordberg, Terex, Telsmith, and other equivalent models. Precision-machined to meet or exceed OEM tolerances, ensuring proper fit and long-lasting performance.

Quality Control:

Each adjustment ring undergoes rigorous inspection including chemical composition analysis, hardness testing, and dimensional verification to guarantee durability, stability, and accurate adjustment of the discharge settings.

Applications:

Mining

Quarrying

Aggregate processing

Cement and construction materials

Metallurgical operations

MOQ: 1 piece

Lead Time: 7–15 working days depending on stock

Payment Terms: T/T, L/C, and other common international payment methods

Warranty: 12 months (subject to working conditions)

Key Features:

Precise Discharge Control: Allows accurate adjustment of the crusher output size.

High Strength & Durability: Forged alloy steel resists wear and maintains structural integrity under heavy load.

OEM-Standard Fit: Machined to strict tolerances for stable operation and proper alignment.

Wide Compatibility: Suitable for cone crushers from Metso, Sandvik, FLSmidth, and other major brands.

Reliable & Safe: Protects upper structure and bearing assembly, ensuring smooth crusher operation.

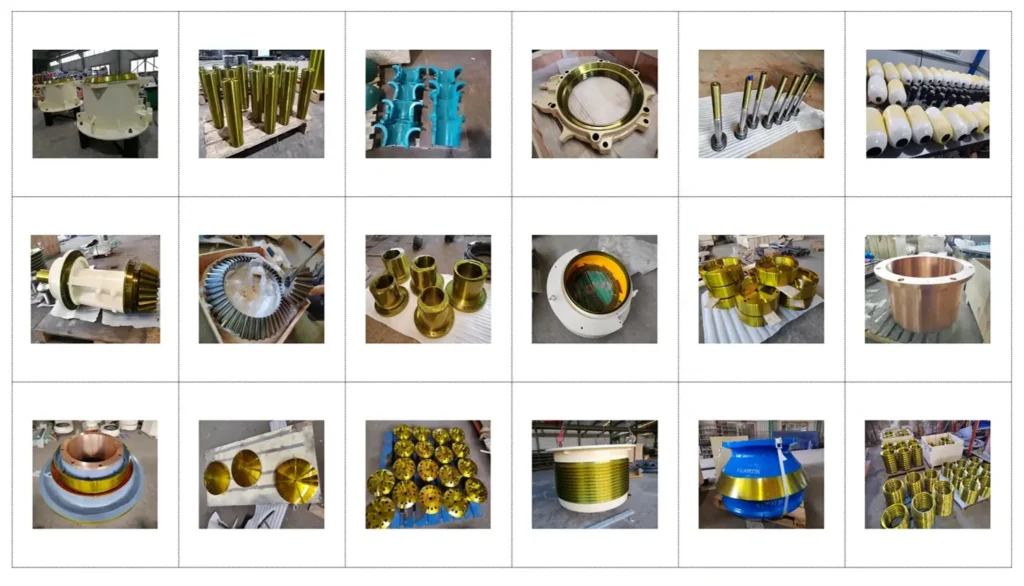

Metalore is a professional aftermarket supplier of cone crusher spare parts. We provide a full range of mantles, concaves, main shafts, adjustment rings, jaw plates, pitmans, toggle plates, side plates, flywheels, hammers, and other replacement components for globally recognized mining and quarrying equipment.

Our products are engineered to OEM standards, ensuring durability, performance, and fast delivery for mining operations worldwide.

We provide all crusher spare parts, including but not limited to the following items