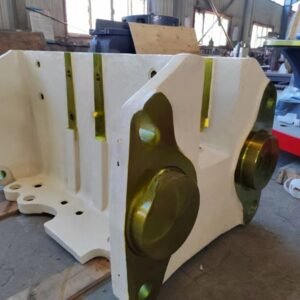

The mantle is a key wear-resistant component of the MMP800 Multi-Cylinder Hydraulic Cone Crusher, designed to crush hard rock and mineral materials by direct contact with the concave (bowl liner). Precision-engineered for high crushing efficiency and long wear life, the mantle is manufactured using high-manganese steel or customized alloy materials to ensure excellent toughness, impact resistance, and abrasion performance.

This mantle is built to meet or exceed original equipment manufacturer (OEM) specifications, offering reliable performance in demanding mining, quarrying, and aggregate crushing applications. Its optimized profile and metallurgical composition help reduce downtime, improve production capacity, and lower operating costs.

Product Name: Mantle for MMP800 Multi-Cylinder Hydraulic Cone Crusher

Application: For crushing hard and abrasive materials in mining, aggregate, and quarry operations

Material: High manganese steel (Mn13Cr2, Mn18Cr2) / Customized alloy steel

Key Features:

Precision-cast and machined for perfect fit and alignment

High wear resistance and excellent impact toughness

Meets OEM or custom specifications for reliable performance

Suitable for secondary and tertiary crushing applications

Designed to maximize crushing output and reduce wear costs

Compatibility: MMP800 / MP800 / Other equivalent cone crusher models

Net Weight: Approx. 700–900 kg (varies by design)

Packaging: Export-ready wooden pallet with anti-corrosion protection

Lead Time: 20–40 working days (depending on production schedule)

Payment Terms: T/T, L/C, or negotiable options

Warranty: 6–12 months (based on material and working conditions)

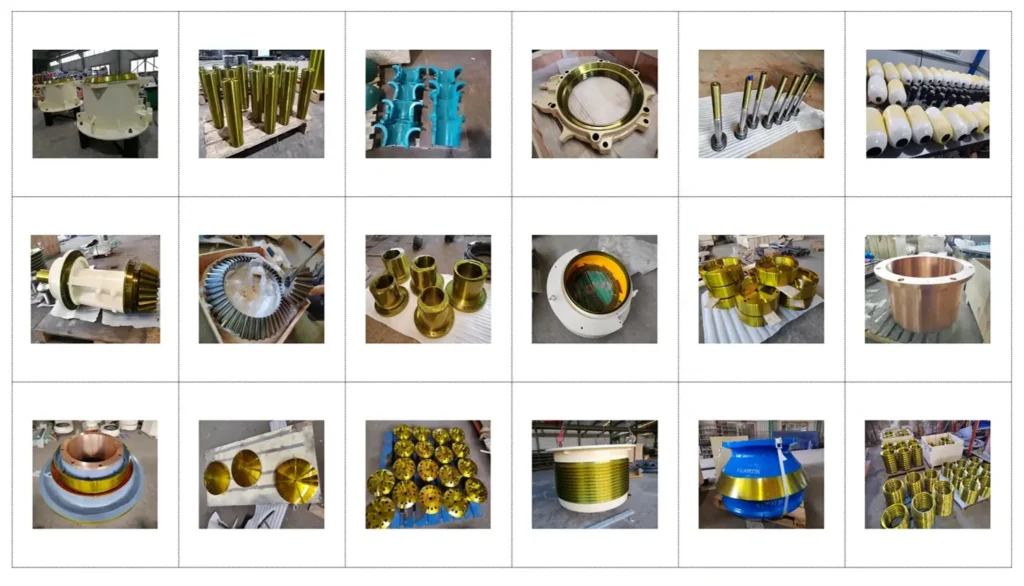

We provide all crusher spare parts, including but not limited to the following items