The jaw plate is one of the most important wear components of a jaw crusher, responsible for crushing and reducing large stones and minerals into smaller, workable sizes. Operating under continuous impact, friction, and high pressure, the jaw plate requires excellent material strength, hardness, and resistance to wear.

Metalore manufactures high-quality jaw plates using premium manganese steel (Mn13Cr2, Mn18Cr2, Mn22Cr2) and alloy materials, designed to deliver extended wear life and reliable performance in demanding mining and quarrying applications.

Our jaw plates are precision-machined to meet or exceed OEM tolerances and are compatible with crushers from internationally recognized brands such as Metso, Sandvik, FLSmidth, Terex, Telsmith, and many other equivalent models.

We also support customized production based on drawings, samples, or specified working conditions, helping our customers reduce downtime and operating costs while increasing output and efficiency.

Key Features

High Wear Resistance

Manufactured from premium manganese and alloy steels for extended service life under heavy crushing conditions.OEM-Standard Fitment

Machined to precise tolerances for perfect fit with jaw frames and tightening systems.Multiple Profiles Available

Standard tooth, deep tooth, corrugated, flat tooth, and customized designs based on working conditions.Wide Compatibility

Suitable for a full range of jaw crusher models from major international mining equipment brands.Strict Quality Control

Hardness testing, chemical analysis, ultrasonic flaw detection, and dimensional inspection performed before delivery.

Material Options & Applications

| Material | Typical Use | Feature |

|---|---|---|

| Mn13Cr2 | Soft rock | High toughness, good impact resistance |

| Mn18Cr2 | Medium hardness rock | Balanced wear and strength |

| Mn22Cr2 | Hard rock | Maximum wear resistance, longer service life |

| TIC Inserts | Extremely abrasive rock | Extended service life in high-impact applications |

Suitable Crusher Models

Metso C Series: C80, C105, C110, C120

Sandvik CJ Series: CJ211, CJ412, CJ612

Terex / Trio / Pegson Jaw Crushers

* Custom profiles are available based on drawings or samples to ensure perfect fit and optimal crushing performance.

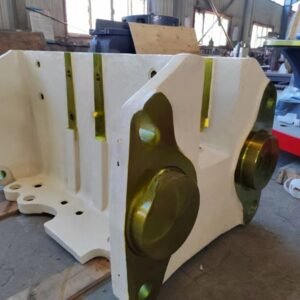

Manufacturing & Quality Assurance

Strict chemical composition control

Advanced heat treatment process

Dimensional and visual inspection

OEM & custom designs available

* We provide jaw plates for OEM replacement and aftermarket support, ensuring your crushers operate at peak efficiency.

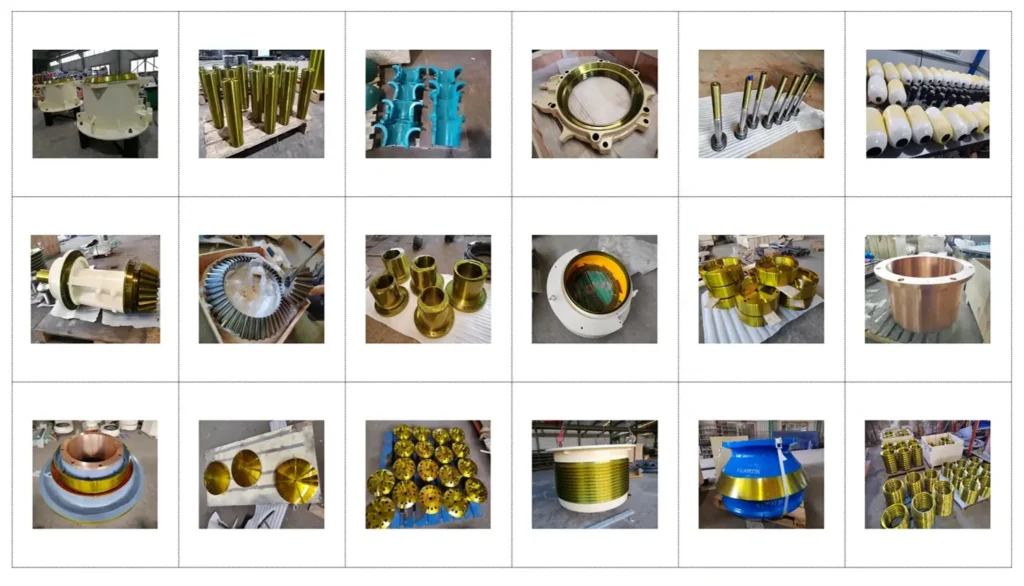

We provide all crusher spare parts, including but not limited to the following items