Jaw Crusher Eccentric Shaft – Aftermarket Replacement

Material: High-Quality Alloy Steel / Custom Materials Available on Request

Product Overview:

The Jaw Crusher Eccentric Shaft is a critical component that plays a pivotal role in the smooth operation of the jaw crusher. Positioned within the crusher’s frame, the eccentric shaft enables the movement of the jaw, allowing it to crush materials effectively. Constructed from high-strength materials, this part is designed to withstand heavy loads and harsh conditions, ensuring long-lasting performance and reduced downtime in demanding mining and aggregate processing environments.

Features:

Superior Strength: Made from high-grade alloy steel to provide exceptional resistance to fatigue, stress, and wear.

Precision Machining: Manufactured to meet OEM tolerances, ensuring a perfect fit and consistent, reliable operation.

Reliable Operation: Designed to maintain optimal performance even under extreme operational conditions, ensuring your jaw crusher functions efficiently.

Durability: Engineered to withstand heavy impacts and high rotational speeds, prolonging service life and minimizing maintenance costs.

Applications:

Mining Operations: Essential for material crushing in hard rock and ore mining.

Aggregate Processing: Critical for efficient processing and reduction of aggregates.

Construction & Demolition: Ideal for breaking down construction debris and aggregates.

Recycling: Suitable for crushing various materials, including concrete, brick, and other recyclables.

Compatibility:

Our Jaw Crusher Eccentric Shaft is compatible with various jaw crusher models from leading manufacturers, including Metso, Sandvik, Terex, Telsmith, and more. Manufactured to OEM specifications, it ensures a perfect fit and reliable performance across a wide range of crushers.

Quality Assurance:

We conduct rigorous testing to ensure that each eccentric shaft meets the highest standards of durability and performance. Our quality control procedures include:

Chemical Composition Analysis: To ensure consistent material quality and strength.

Hardness Testing: To verify its resistance to wear and tear during heavy crushing operations.

Dimensional Control: To ensure the eccentric shaft fits precisely and operates without issue.

Ordering Information:

MOQ: 1 piece

Lead Time: 7–15 working days (depending on stock availability)

Payment Terms: T/T, L/C, and other common international methods

Warranty: 12 months (subject to working conditions)

Key Benefits:

High-Strength Materials: Premium alloy steel for superior wear resistance and long-lasting performance.

Precision Fit: Machined to OEM tolerances for optimal alignment and efficient jaw crusher operation.

Broad Compatibility: Compatible with crushers from Metso, Sandvik, Telsmith, and other major brands.

Enhanced Performance: Ensures smooth and consistent jaw movement for maximum crushing efficiency.

About Metalore:

As a leading supplier of aftermarket jaw crusher parts, Metalore offers a full range of high-quality replacement components. Our products, including eccentric shafts, jaws, bearings, and more, are engineered for durability and efficiency in the most demanding industries.

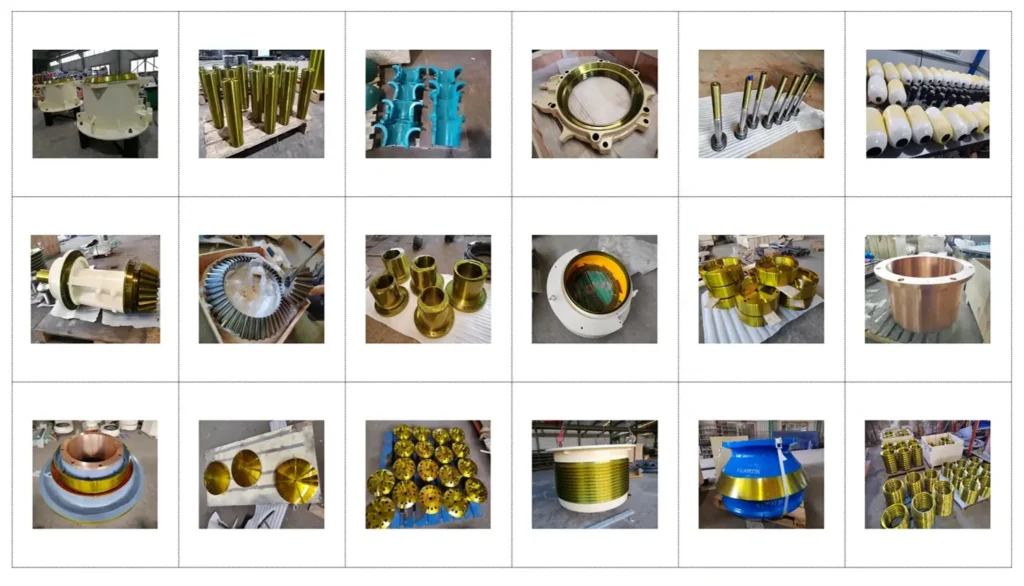

We provide all crusher spare parts, including but not limited to the following items