People usually search for jaw crusher parts when something has already gone wrong.

The crusher is running, but wear is too fast, downtime keeps increasing, or parts don’t last as long as they used to.

On paper, jaw crushers are simple machines.

In reality, most problems come from small parts being wrongly selected or ignored.

Below are a few things that matter in real operation — not in brochures.

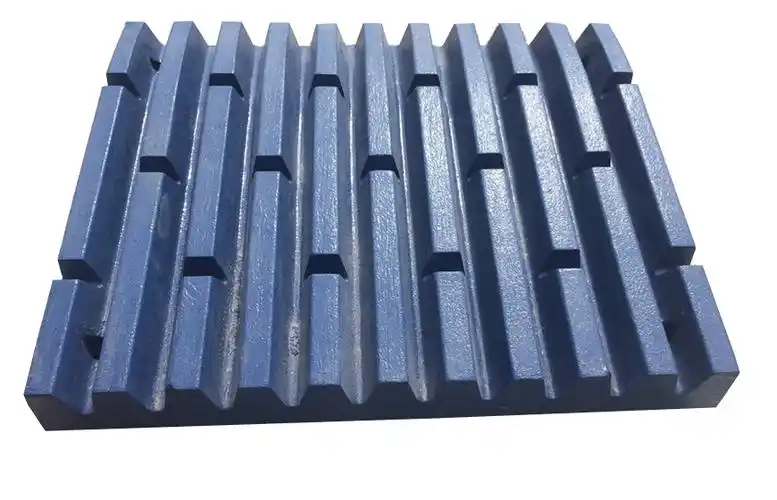

Jaw Plates Don’t Wear Fast by Accident

Jaw plates are supposed to wear.

But when they wear too fast, there is almost always a reason.

Common causes we see:

The tooth profile doesn’t match the material

Feed size is larger than the crusher was designed for

The material is abrasive but doesn’t allow proper work hardening

Higher manganese is not always the answer.

In some applications, a “harder-looking” plate never hardens properly and ends up wearing faster than a standard grade.

This is why two sites crushing the same material can get completely different jaw plate life.

Cheek Plates Are Usually Replaced Too Late

Cheek plates don’t get much attention until the frame is already at risk.

In many plants:

Jaw plates still look usable

Cheek plates are already thin

Side wear starts affecting the crusher body

Once the frame is damaged, replacement parts no longer fit the same way.

That’s when vibration increases and wear accelerates across the whole machine.

Cheek plates are not expensive — frame repairs are.

Toggle Plates Are Meant to Break

This sounds obvious, but it’s ignored all the time.

A toggle plate is a safety component, not a strength upgrade.

When operators replace a broken toggle plate with a stronger one, the weak point simply moves somewhere else.

What usually fails next:

Crusher frame

Bearings

Eccentric shaft components

A broken toggle plate is inconvenient.

A cracked frame is a long shutdown.

Bearings and Seals Cause More Downtime Than Wear Parts

Many jaw crushers stop not because of worn jaw plates, but because of bearing problems.

Typical reasons:

Dust entering through poor sealing

Incorrect lubrication

Bearings not suited for continuous heavy loads

Once a bearing fails, the crusher doesn’t just stop —

alignment, shafts, and housings often suffer damage as well.

Good seals and correct bearing selection save more downtime than any wear part upgrade.

OEM or Aftermarket Jaw Crusher Parts? Most Sites Use Both

In real operations, the choice is rarely “OEM only” or “aftermarket only”.

What experienced operators do:

Use OEM parts for critical or warranty-related components

Use high-quality aftermarket jaw crusher parts for wear items

The key difference is not the label — it’s application knowledge.

A supplier who asks about:

Material type

Operating hours

Past failure points

…is far more valuable than one who only asks for a part number.

The Real Cost of Jaw Crusher Parts Is Downtime

The price of a part is easy to see.

The cost of downtime is not.

Frequent replacement leads to:

Lost production

Extra labor

Higher energy consumption

Unstable crusher performance

In many cases, a slightly more expensive part results in a lower cost per ton over time.

Final Thought

Jaw crusher parts are not just replacements —

they determine how stable and predictable your crusher runs.

When parts are selected based on real operating conditions, jaw crushers are among the most reliable machines in a plant.

Most problems start when parts are chosen only by catalog, not by experience.