Finding a crusher wear parts supplier sounds easy — until your machine is down and the wrong part shows up.

Many buyers focus only on price, but in reality, the wrong manufacturer can cost far more through downtime, rework, and lost production. This article shares a practical way to choose the right crusher wear parts manufacturer, based on real sourcing experience.

Why Many Buyers Choose the Wrong Supplier

Most problems start the same way:

a rushed inquiry, unclear information, and a supplier who says “yes” too quickly.

When wear parts don’t fit or wear out too fast, it’s usually not bad luck — it’s poor identification or material selection. Crusher wear parts are not generic items. Even small differences in profile, thickness, or alloy can significantly affect performance.

Choosing the right manufacturer is about accuracy first, price second.

The One Thing That Makes Quoting Fast and Accurate

If you want a fast and accurate quotation, there is one piece of information that matters more than anything else:

The part number.

A part number allows the manufacturer to:

Identify the exact drawing

Confirm dimensions and weight

Match the correct material specification

Quote without guesswork

With a part number, a professional supplier can usually quote within hours.

Without it, the process often turns into long email chains, photos, and repeated confirmations.

If efficiency matters to you, always start with the part number.

How to Find the Part Number If You Don’t Have It

If you don’t know the part number, don’t panic. There are three practical ways to find it.

1. Check the Old Wear Part

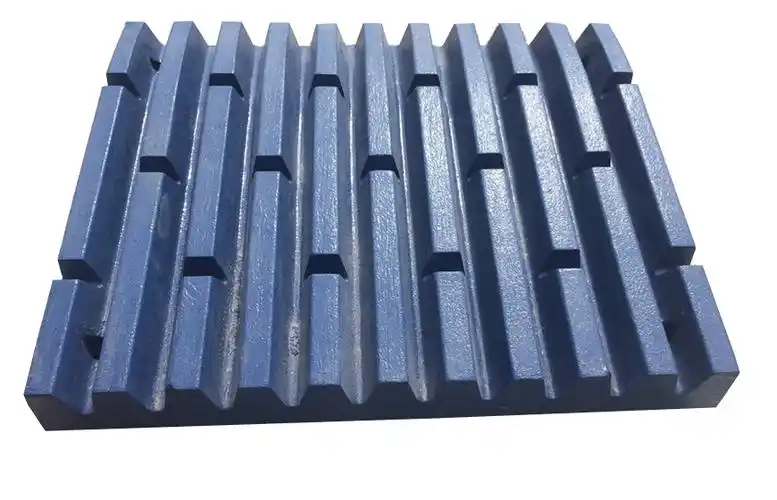

Many jaw plates, mantles, bowl liners, and blow bars have cast or stamped numbers. Clean the surface and check flat areas, edges, or near bolt holes.

2. Use the Crusher Parts Manual

The parts manual includes exploded diagrams where each component is linked to a part number. Even older machines often have PDF manuals available online.

3. Ask an Experienced Supplier

If neither option works, a professional manufacturer can help identify the part using:

Crusher brand

Model

Serial number (if available)

An experienced supplier will confirm details instead of guessing.

No Part Number, No Manual, No Problem

Older machines and second-hand equipment are common in mining and quarrying. In these cases, reverse engineering is a practical solution.

By measuring the worn part and sharing:

Key dimensions

Photos from multiple angles

Weight (if possible)

A capable manufacturer can create a technical drawing and reproduce the part accurately. This process takes more effort, but it keeps valuable equipment running instead of being scrapped.

How to Judge a Manufacturer Beyond Price

Once you have the part number, you’ll likely receive multiple quotes. Prices may look similar — or very different. Here’s what actually matters:

Experience With Major Brands

A reliable manufacturer should be familiar with OEM standards for brands like Metso, Sandvik, or Symons. Proven drawings reduce fitment risks.

Material Knowledge

Not all manganese steel performs the same. A good supplier will discuss:

Rock type

Abrasiveness

Recommended alloy (Mn13, Mn18, Mn22, etc.)

If no questions are asked, material selection is probably generic.

Technical Support

Good manufacturers help identify parts, confirm drawings, and avoid mistakes — not just take orders.

Long-Term Value

A slightly higher-priced wear part that lasts longer often delivers better cost per ton and less downtime.

Final Thoughts

Choosing the right crusher wear parts manufacturer starts with clear information — especially the part number. But long-term success comes from working with a supplier who understands your equipment, materials, and operating conditions.

The right partner doesn’t just sell wear parts.

They help keep your crushers running.