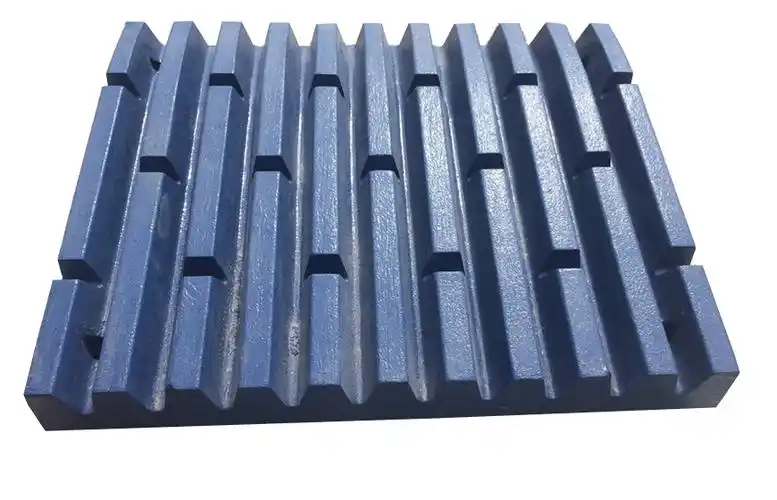

The cone crusher mantle is one of the most critical wear parts in any crushing operation. Proper maintenance and careful operation can significantly extend its lifespan, reduce downtime, and save costs for mining and aggregate operations.

1. Choose the Right Mantle Material and Profile

Selecting the correct mantle material is the first step to longer wear life. Different ores require different grades:

Mn13–Mn18: Suitable for softer ores like limestone.

Mn18–Mn22 or TIC inserts: Ideal for hard and abrasive ores like granite, basalt, or iron ore.

Equally important is the mantle profile. Short-head mantles produce finer output but wear faster, while standard profiles offer a balance between output and wear. Always match the profile to your crusher type and feed conditions.

2. Maintain Consistent Feed Size and Distribution

Uneven feed can cause localized wear and reduce mantle life. Best practices include:

Use a grizzly or feeder to remove fines before crushing.

Avoid feeding oversized rocks that exceed the crusher’s design.

Ensure even distribution across the mantle, preventing uneven pressure points.

3. Monitor Crusher Operation Parameters

Regularly check crusher operating conditions:

Maintain correct hydraulic pressure to protect the mantle and concave.

Avoid overloading the crusher, as excessive stress accelerates wear.

Monitor crusher speed and stroke to ensure consistent crushing efficiency.

4. Regular Inspection and Preventive Maintenance

Scheduled inspections can catch early signs of wear:

Check mantle thickness and surface condition.

Inspect concave wear patterns to prevent uneven stress on the mantle.

Replace worn mantles before they reach critical wear levels to avoid damage to other crusher components.

5. Use Quality Spare Parts and OEM Replacements

Investing in high-quality cone crusher wear parts ensures longer service life:

OEM or premium aftermarket mantles provide consistent material properties.

Custom mantles designed for your specific application can further reduce wear.

Keep an inventory of replacement mantles and concaves to minimize downtime.

6. Train Operators on Best Practices

Operator knowledge is key to wear life:

Avoid “shock feeding” or sudden surges of large rocks.

Monitor crusher performance daily.

Follow recommended maintenance schedules from the manufacturer or supplier.

Final Thoughts

Extending cone crusher mantle wear life is not about a single trick—it requires a combination of material selection, proper operation, preventive maintenance, and quality spare parts. By following these steps, mining and aggregate operators can reduce costs, improve crusher efficiency, and maximize production uptime.