Choosing the right cone crusher mantle is crucial for maximizing crusher efficiency, reducing downtime, and extending the life of your equipment. Different rock types have varying hardness, abrasiveness, and size distribution, which directly affects the performance of the mantle and other crusher wear parts.

1. Understand Your Rock Type

Before selecting a mantle, you must know the type of rock your crusher will handle:

Soft rock (limestone, gypsum): Low abrasiveness, easy to crush. Standard manganese steel mantles are usually sufficient.

Medium hardness rock (granite, basalt, quartzite): Moderate abrasiveness. Choose mantles with higher manganese content (Mn14–Mn18) for longer wear life.

Hard and abrasive rock (iron ore, hard granite): Highly abrasive and tough. High manganese steel or alloyed mantles are recommended to resist wear and impact.

Knowing the Mohs hardness and abrasiveness of your material helps prevent premature wear and ensures the crusher operates efficiently.

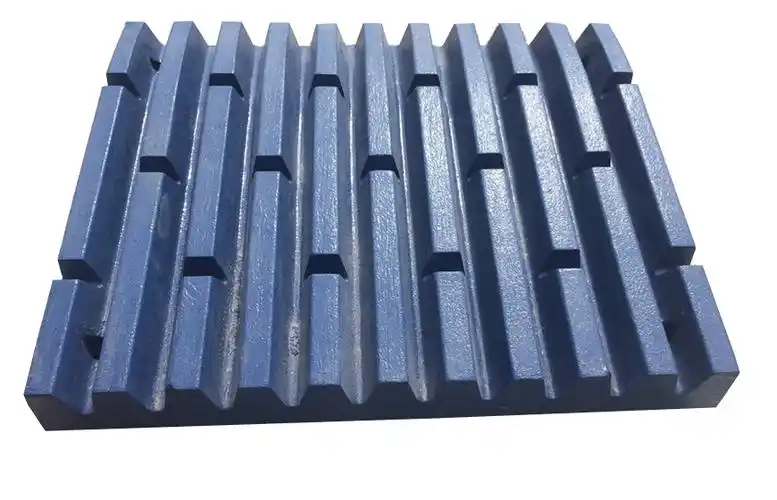

2. Match Mantle Design to Your Application

Cone crusher mantles come in different profiles and designs. Selecting the right one depends on your application:

Standard Mantle: Suitable for general-purpose crushing of medium-hard rock.

Short Head Mantle: Provides finer output and is used in secondary or tertiary crushing.

Steep Angle Mantle: Improves reduction ratio for hard, abrasive rock but may wear faster if the rock is soft.

Always consider your crushing stages and the desired product size when choosing the mantle profile.

3. Consider the Material Thickness and Manganese Grade

Material thickness: Thicker mantles can last longer but may reduce crushing efficiency slightly. Thinner mantles wear faster but can improve product size distribution.

Manganese grade: High manganese steel mantles (Mn14–Mn22) are common for abrasive applications. For extremely hard rock, alloyed mantles with added chromium or nickel can improve wear resistance.

Balancing mantle thickness and material grade is key to optimizing wear life while maintaining throughput.

4. Replacement Timing and Maintenance

Even with the right mantle, regular monitoring is essential:

Inspect mantles for uneven wear, cracks, or chipping.

Maintain proper crusher setting to avoid excessive load on the mantle.

Replace worn mantles before they damage the concave or other crusher wear parts.

Proper maintenance not only extends the mantle life but also prevents unexpected downtime and costly repairs.

5. Choosing the Right Supplier

Selecting a reliable supplier for replacement mantles ensures quality and compatibility. At Metalore, we provide mantles compatible with Metso, Sandvik, Terex, and other major brands. All our mantles are made of high-quality manganese steel and precision-engineered to match OEM specifications.

Conclusion

Choosing the correct cone crusher mantle depends on understanding your rock type, mantle design, material grade, and maintenance schedule. The right selection can significantly improve crusher efficiency, reduce wear costs, and extend equipment life. Always work with trusted suppliers to ensure high-quality replacement parts that match your crusher model.