When it comes to maintaining and improving the efficiency of your crushing equipment, choosing the right cone crusher bowl liner is critical. As a key part of your crusher’s wear components, the bowl liner directly influences performance, durability, and overall production efficiency. Whether you’re looking for high-quality crusher wear parts or seeking to replace your current liners, selecting the perfect one requires some careful thought.

In this guide, we’ll break down how to select the ideal cone crusher bowl liner for different crushing applications, ensuring that you get the best value and performance for your equipment.

Understand the Type of Material You’re Crushing

The first step in choosing the right bowl liner is understanding the type of material you’re crushing. Different materials have varying hardness and abrasiveness, which can impact how well your liners perform.

Harder materials (like granite or basalt) require liners made from stronger, more wear-resistant materials such as manganese steel or alloy steel. These materials help the liner last longer and maintain its shape under the extreme pressure of hard rock crushing.

Softer materials (such as limestone or sand) may not wear down the liner as quickly, allowing you to choose a liner with slightly less abrasion resistance without sacrificing longevity.

By matching the bowl liner material to the material being crushed, you can maximize both performance and cost-efficiency.

Consider the Crushing Process and Equipment

Next, consider the specifics of your crushing process and the type of cone crusher you’re using. Different crushers operate under different conditions, and the type of bowl liner you choose must match these conditions.

Secondary crushing applications generally require liners with a slightly more aggressive profile for finer output.

Primary crushing may call for more durable liners with a focus on impact resistance to handle the larger rocks and more abrasive conditions.

Knowing whether your crusher is used for primary, secondary, or even tertiary crushing will guide you toward the correct choice.

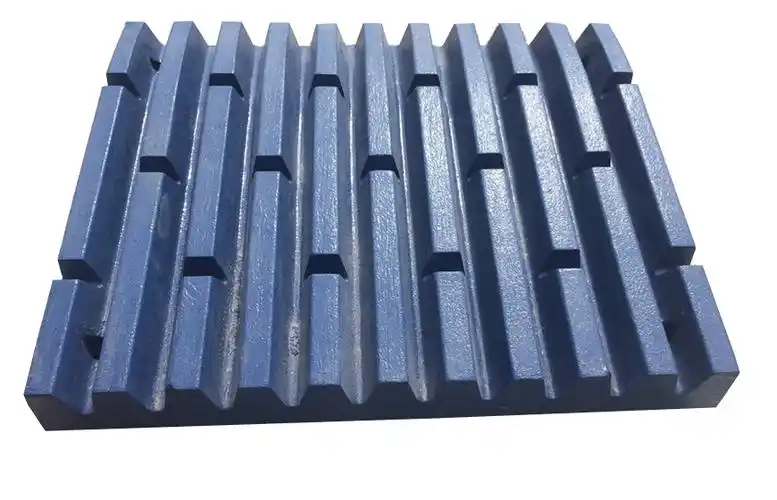

Liner Profile and Design

Not all cone crusher bowl liners are created equal. They come in a variety of designs, and choosing the right liner profile is essential for maximizing efficiency and minimizing downtime.

Shallow profile liners are ideal for fine crushing, providing higher throughput and better shape for smaller materials.

Steep profile liners work best for coarse crushing, where larger, tougher materials are being broken down, and the liner needs to withstand higher forces.

Matching the liner profile to your crushing needs ensures optimal throughput and final product quality.

Quality and Durability of Materials

As with any crusher wear part, the quality and durability of the material are key to ensuring long-lasting performance. A high-quality bowl liner will reduce the frequency of replacements, improve productivity, and ultimately save you money on downtime and labor.

OEM (Original Equipment Manufacturer) parts are often the safest bet for ensuring high-quality materials that match the specifications of your crusher.

However, many reputable suppliers also offer aftermarket bowl liners that provide excellent performance at a more competitive price.

When considering your options, always check the material composition and brand reputation. High manganese steel, alloy steels, and other high-performance materials are preferred for their wear resistance and ability to handle extreme crushing conditions.

Matching the Liner to Crusher Model

It’s important to match the bowl liner with the specific model of your cone crusher. Many cone crushers are designed with specific liner configurations in mind, and selecting the wrong size or design can lead to decreased performance or equipment failure.

Be sure to check the OEM part number or refer to the crusher model specifications to ensure compatibility. If you’re working with a non-OEM part, consult with the supplier to ensure it’s designed to match your crusher’s requirements.

Consider the Cost of Ownership

While price is always a consideration when purchasing new parts, it’s important to think beyond the upfront cost of a cone crusher bowl liner. Look at the total cost of ownership—including how long the liner will last, how frequently it needs to be replaced, and the impact on crusher downtime.

Durable liners may come with a higher initial price, but their longer lifespan and reduced maintenance costs can make them more cost-effective in the long run.

Lower-cost liners might require more frequent replacements, leading to more downtime and higher long-term costs.

Evaluate the value over time rather than just the purchase price to ensure you’re making a wise investment.

Conclusion: Choose the Right Bowl Liner for Maximum Efficiency

Selecting the right cone crusher bowl liner for your specific crushing application requires a combination of material knowledge, understanding your equipment’s specifications, and evaluating factors like durability and cost. Whether you are replacing liners in Metso, Sandvik, or another brand of crushers, it’s essential to consider all aspects to maximize performance, minimize downtime, and reduce the total cost of ownership.

By following these guidelines, you can ensure that your crusher bowl liners will provide the best fit, durability, and value for your crushing operations. So, when it’s time to replace or upgrade your liners, take the time to make an informed decision that will benefit your business for years to come.