Our crusher hammers for hammer crushers are engineered as critical wear parts for demanding crushing operations in cement plants, mining, metallurgy, power generation and building materials industries.

Designed for medium to hard and high-hardness materials such as limestone, granite, basalt, slag and coal gangue, these hammers deliver outstanding wear resistance, impact strength and extended service life.

By combining advanced material science with optimized casting and heat treatment technologies, we provide a reliable crushing solution that reduces wear cost per ton, minimizes downtime, and significantly improves overall operational efficiency.

Key Advantages & Technical Highlights

Exceptional Wear Resistance & Long Service Life

Advanced casting technologies

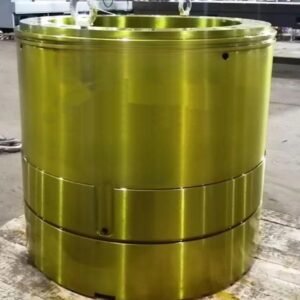

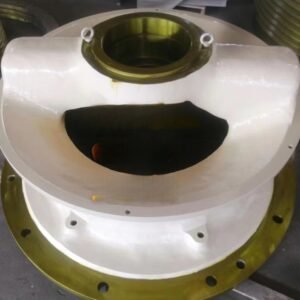

Manufactured using V-process casting, lost foam casting, or bimetal composite casting, ensuring a dense, defect-free structure with a strong metallurgical bond between the wear-resistant working zone and the tough support zone.High hardness, superior abrasion resistance

The working surface hardness reaches HRC 58–65 or above, effectively resisting cutting and impact wear, with service life far exceeding conventional manganese steel hammers.

Excellent Impact Resistance & Safety

Through optimized alloy design and controlled heat treatment processes (oil quenching, air quenching, etc.), the hammer maintains sufficient internal toughness while achieving high surface hardness.

Capable of withstanding repeated high-impact loads during crushing operations, reducing the risk of cracking or premature failure.

Optimized Structural Design

Designed based on rotor dynamics and impact mechanics, ensuring accurate weight distribution, stable rotor operation, strong impact force and high crushing efficiency.

Multiple hammer profiles available, including light-duty, heavy-duty, bimetal hammers and alloy-inserted designs, tailored to different materials and crusher models for precise matching.

Superior Economic Performance

Lower cost per ton

Although the initial unit price may be higher, the significantly longer service life results in fewer replacements, reduced spare parts consumption and lower maintenance labor costs.Higher overall productivity

Less downtime and higher equipment availability ensure continuous production and greater long-term economic benefits.

Typical Technical Specifications

(Can be customized according to your drawings or samples)

Suitable materials: Limestone, dolomite, coal gangue, medium-hard ores, construction waste, etc.

Hardness:

Working zone: HRC 58–65

Mounting / impact zone: HRC 35–45

Tensile strength: ≥ 850 MPa (depending on material grade)

Impact toughness: ≥ 8 J/cm² (depending on material grade)

Manufacturing process: Precision casting + optimized heat treatment

Single weight range: 5 kg – 150 kg, OEM replacement or custom-made according to customer requirements