Customized Solutions for Efficient Quarry & Aggregate Production

Metalore Delivering Reliable Crushing Plant Solutions

Selecting the right quarry crushing plant is critical to ensure:

Stable output and target production capacity

Minimized wear parts consumption and maintenance downtime

Optimized operational cost and energy efficiency

Metalore provides engineering-focused solutions, coordinating equipment supply, layout planning, and project implementation to meet each client’s unique requirements.

Key Engineering Considerations

Our approach prioritizes practical project outcomes, not generic equipment lists:

Material characteristics and hardness

Required capacity and target output gradation

Feeding conditions and site layout constraints

Number of crushing stages and optimal configuration

Wear parts management and maintenance accessibility

Addressing these factors upfront reduces project risk and ensures long-term reliability.

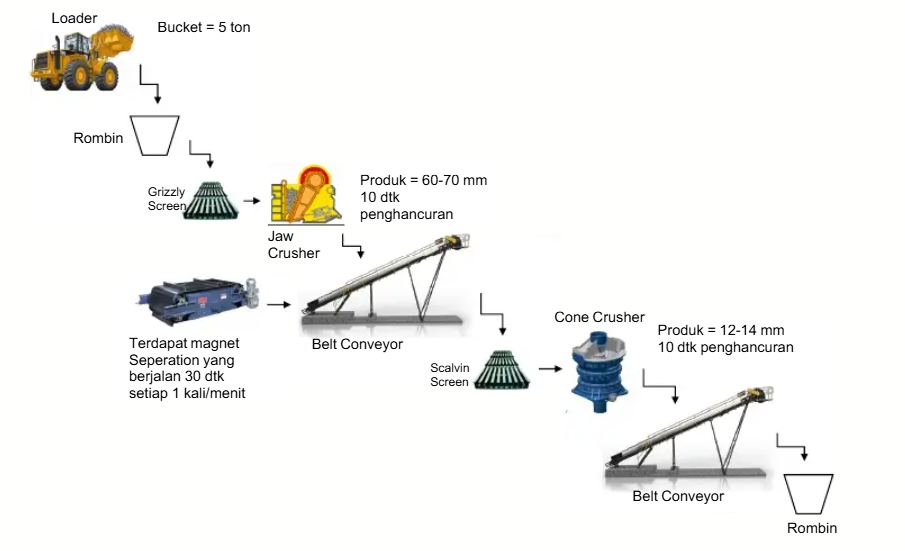

Typical Crushing Plant Configuration

A well-planned plant may include:

Feeding System

Vibrating feeder with controlled feed

Adjustable hopper for material flow stability

Primary Crushing

Jaw crusher for coarse reduction

Optimized for feed size and throughput

Secondary / Tertiary Crushing

Cone crusher or impact crusher for target gradation

Adjustable settings to balance output and wear parts life

Screening System

Vibrating screens for size classification

Re-circulation loops for maximizing yield

Conveying System

Belt conveyors connecting all stages

Ensures continuous material flow and minimal downtime

Capacity Ranges

Metalore’s solutions accommodate a broad spectrum of production requirements:

50–100 TPH quarry plants

100–200 TPH aggregate plants

200–300 TPH stone crushing lines

Custom higher-capacity plants on request

Capacity is determined based on material, desired output, and site layout.

Application Scope

Our solutions are suitable for processing:

Limestone

Basalt

Granite

River stone

Other quarry or aggregate materials

Each application is analyzed individually to ensure efficiency and durability.

Project Implementation Process

Metalore manages the full project cycle:

Requirement analysis and material evaluation

Process flow and layout planning

Equipment coordination and procurement

Delivery, installation, and commissioning support

Long-term spare parts and maintenance support

This structured approach guarantees predictable performance and project success.

Why Work with Metalore?

Engineering-oriented solution provider, not just an equipment supplier

Custom configurations tailored to project-specific requirements

Integrated equipment sourcing and project coordination

Focus on reducing operating costs and maximizing uptime

Reliable spare parts and wear parts support

Metalore ensures that your quarry crushing plant is designed and implemented for long-term efficiency and reliability.