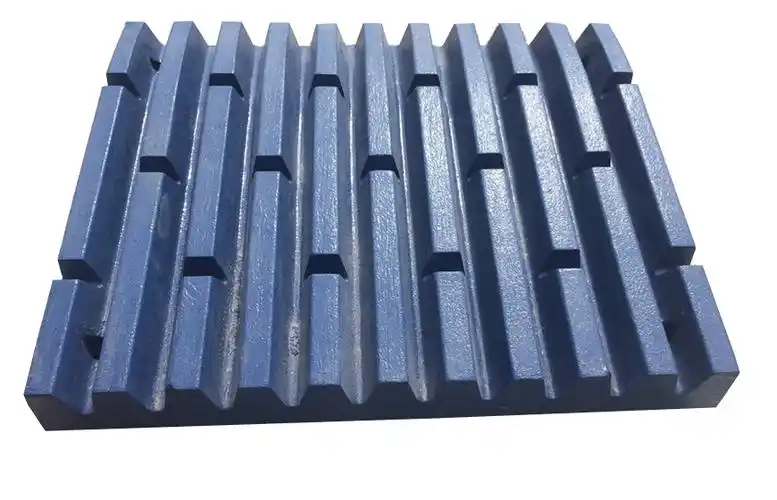

The jaw plate is a critical component in a crusher. Choosing the wrong replacement can lead to fast wear, reduced output, or even unplanned downtime. Here’s what you need to focus on:

Material Compatibility

High Manganese Steel (Mn13–Mn18): Suitable for general ore crushing, cost-effective.

High Chromium Cast Iron: Best for harder ores or materials with impurities, offering higher wear resistance.

⚠️ Note: Material selection directly affects lifespan and depends on ore hardness and moisture content.

Model and Specification

Ensure the jaw plate model matches your crusher exactly.

For replacement parts, use certified or tested compatible models to avoid installation issues or reduced efficiency.

Wear Resistance and Lifespan

Prioritize products with clear wear data.

Some suppliers offer reinforced or coated plates for longer service life.

Supplier Capability

Reliable supply and timely delivery prevent costly downtime.

Prefer suppliers who provide technical support, installation guidance, and after-sales service.

Cost vs Value

Don’t just chase low price; low-quality plates wear out quickly and increase total cost.

Opt for parts that balance quality and lifespan to reduce replacement frequency and labor costs.

Pro Tip: Request material data, wear test reports, and model compatibility from your supplier before purchase. This step is critical for maintaining production efficiency.