For mining and aggregate operations, a jaw crusher is the backbone of the crushing process. Any downtime can result in production delays, increased operational costs, and missed deadlines. Understanding the most common jaw crusher problems and having the right jaw crusher spare parts ready is essential for any operation. This guide will help you identify issues early and implement solutions that minimize downtime and extend equipment life.

Fast Jaw Plate Wear

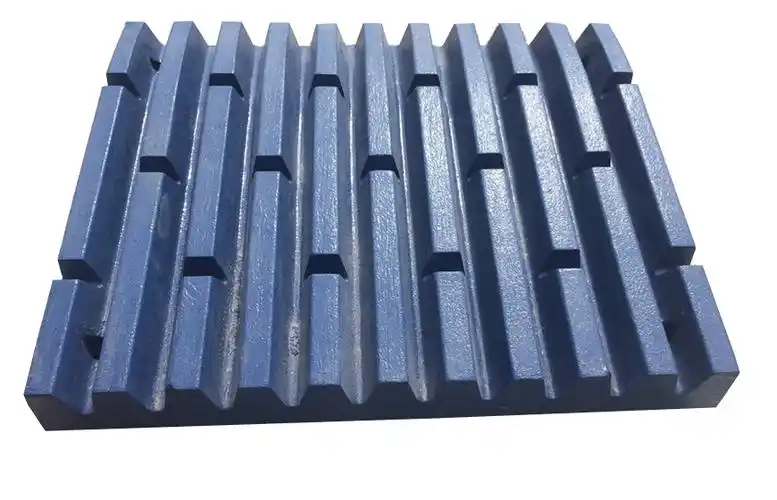

One of the most frequent issues in jaw crusher maintenance is rapid wear of the jaw plates. Over time, high-impact crushing and abrasive materials can cause the plates to deteriorate quickly.

Causes:

Crushing hard ores like granite, basalt, or iron ore.

High material moisture content causing uneven wear.

Using low-quality replacement jaw plates that are not compatible with the crusher model.

Solutions:

Select high-quality replacement jaw plates made from high manganese steel (Mn13–Mn18) for standard ores or high chromium cast iron for harder, abrasive materials.

Check jaw plate thickness regularly and replace before it reaches the minimum safe level.

Ensure the replacement parts match the crusher model exactly to avoid misalignment or reduced efficiency.

Tip: Reliable suppliers can provide tested Metso or Sandvik replacement parts that are compatible with most standard jaw crushers. Investing in high-quality components reduces long-term maintenance costs and keeps production on track.

Spring Breakage and Hydraulic Cylinder Issues

Jaw crusher springs and hydraulic cylinders are critical for proper operation. Breakage or malfunction can halt production entirely.

Causes:

Overloading the crusher beyond its rated capacity.

Incorrect installation or assembly.

Natural wear due to age and heavy usage.

Solutions:

Replace broken or worn springs and hydraulic cylinders with certified replacement parts.

Ensure proper installation, following the manufacturer’s guidelines.

Keep spare components on hand to avoid extended downtime during replacements.

Tip: Some operators maintain a small inventory of high-wear crusher spare parts to ensure immediate availability, especially during peak production periods.

Eccentric Shaft and Bearing Wear

The eccentric shaft and bearings are vital for smooth jaw crusher operation. Wear in these components can lead to vibration, misalignment, and even catastrophic failures.

Causes:

Insufficient lubrication or contaminated oil.

Heavy load or uneven material feed.

Poor-quality bearings or improper installation.

Solutions:

Regularly check the lubrication system and ensure the correct type of oil is used.

Replace worn bearings with high-quality, wear-resistant replacements.

Inspect the eccentric shaft and bushings during scheduled maintenance and replace them if signs of excessive wear are detected.

Tip: Using precision jaw crusher replacement parts ensures alignment and prolongs the lifespan of critical components.

Loose Bolts and Frame Cracks

Vibration during crushing can loosen bolts or even cause cracks in the crusher frame over time. Ignoring these issues can compromise safety and lead to costly repairs.

Causes:

Continuous heavy-duty operation.

Inadequate preventive maintenance.

Using substandard fasteners or ignoring torque specifications.

Solutions:

Implement a preventive maintenance plan that includes regular bolt checks and tightening.

Inspect the crusher frame for cracks and repair or replace damaged sections promptly.

Use high-strength fasteners and follow manufacturer torque recommendations.

Tip: Regular maintenance logs help operators track wear patterns and prevent unexpected equipment failure.

Conveyor and Feed System Issues

A jaw crusher is part of a larger system that includes conveyors and feeders. Problems in these areas often appear as irregular feed, material blockage, or uneven wear on jaw plates.

Causes:

Overfeeding or uneven material distribution.

Blockages due to oversized rocks or foreign objects.

Worn or misaligned conveyor belts and feeders.

Solutions:

Monitor feed size and distribution to avoid overloading the crusher.

Remove blockages immediately and check for underlying causes.

Replace or adjust conveyor belts and feeder mechanisms as needed.

Tip: A well-maintained feed system prolongs the life of jaw crusher spare parts and reduces maintenance frequency.

Practical Tips for Maintenance and Spare Parts Management

Effective crusher maintenance goes beyond just replacing worn components. It involves strategic planning and inventory management to ensure smooth operation:

Maintain an Inventory of Critical Spare Parts

Jaw plates, bearings, bushings, springs, and hydraulic cylinders should always be available.

Prioritize high-wear components to minimize production interruptions.

Schedule Regular Inspections

Include jaw plate thickness checks, bearing inspections, and hydraulic system assessments in your routine.

Early detection prevents small issues from becoming major problems.

Use High-Quality Replacement Parts

OEM parts from Metso, Sandvik, or certified equivalents guarantee compatibility and durability.

Avoid low-cost generic parts that may save money initially but wear out faster and increase downtime.

Keep Detailed Maintenance Records

Track component replacement dates, wear rates, and downtime events.

Analyze data to predict maintenance needs and optimize parts inventory.

Conclusion

Managing a jaw crusher efficiently requires a combination of proactive maintenance, quality replacement parts, and careful monitoring of key components. Rapid jaw plate wear, spring breakage, bearing failure, loose bolts, and feed system issues are common challenges that can be mitigated with proper planning. By maintaining a supply of high-quality jaw crusher spare parts and implementing a regular inspection routine, operators can maximize uptime, reduce repair costs, and maintain consistent production levels.