Equipment Selection Based on Hardness, Capacity & Product Size

Iron ore crushing presents a unique challenge:

high hardness, strong abrasiveness, and large-scale production demands.

Selecting the right crusher is less about brand and more about matching equipment to iron ore characteristics.

1. Iron Ore Characteristics That Affect Crusher Choice

Iron ore typically features:

High compressive strength

Strong abrasiveness

Dense structure

Large feed size after blasting

These properties eliminate many crusher types from consideration early.

2. Primary Crushing for Iron Ore

Best choice: Jaw Crusher or Gyratory Crusher

Jaw crushers are preferred when:

Feed size is irregular

Mine operates under varying conditions

Flexibility and reliability are priorities

Gyratory crushers are suitable when:

Very high capacity is required

Feeding is continuous and controlled

👉 In most medium to large iron ore mines, jaw crushers remain the most practical solution.

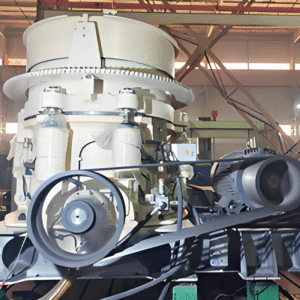

3. Secondary Crushing: Why Cone Crushers Dominate

For iron ore, cone crushers are the industry standard in secondary crushing.

Key reasons:

High crushing force for hard rock

Excellent wear resistance

Stable product size distribution

Impact crushers are rarely used due to:

Excessive blow bar wear

High maintenance frequency

4. Tertiary Crushing for Iron Ore (When Required)

Not all iron ore plants need tertiary crushing.

It becomes necessary when:

Final product size < 15 mm

Grinding efficiency must be improved

Downstream processing requires uniform feed

Recommended equipment:

Short-head cone crusher

High-performance cone with fine chamber

5. Recommended Iron Ore Crushing Configuration

| Stage | Equipment | Purpose |

|---|---|---|

| Primary | Jaw Crusher | Handle large, hard feed |

| Secondary | Cone Crusher | Major size reduction |

| Tertiary (optional) | Fine Cone | Final size control |

6. Wear Parts Considerations for Iron Ore

Iron ore crushing places extreme stress on wear parts.

To reduce cost:

Use correct chamber selection

Optimize feed distribution

Select wear-resistant aftermarket liners

High-quality OEM alternative wear parts can:

Match original performance

Reduce replacement frequency

Lower overall operating cost

Conclusion

The best crusher for iron ore is not a single machine, but a well-matched crushing system.

Proper selection ensures:

Stable production

Controlled wear cost

Long-term operational efficiency