Selecting the right cone crusher mantle is not just about matching a model number. Different ores behave very differently during crushing, and the wrong mantle choice can lead to excessive wear, unstable operation, or unnecessary downtime.

Based on real mining applications, this guide explains how to choose the most suitable cone crusher mantle for different ore types, helping you improve wear life and overall crushing efficiency.

Why Ore Type Matters in Mantle Selection

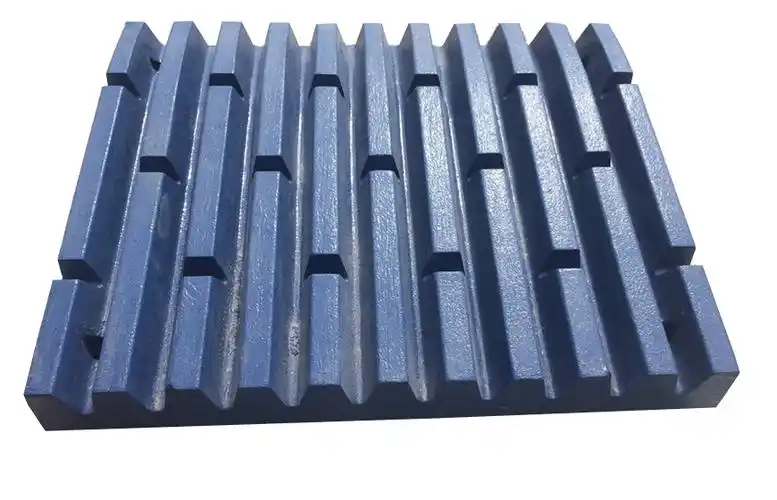

In cone crushing, the mantle works together with the concave to break material through continuous compression.

Ore characteristics such as hardness, abrasiveness, moisture content, and particle shape directly affect how fast the mantle wears.

A mantle that performs well in limestone may fail quickly in granite or iron ore. That’s why experienced operators always select mantle material and profile based on the actual ore conditions, not just the crusher brand.

Mantle Selection for Common Ore Types

Limestone and Dolomite (Soft to Medium-Hard Rock)

Limestone is relatively soft and less abrasive, which makes it one of the easiest materials for cone crushers.

Recommended mantle material:

Mn13 (Standard manganese steel)

Why it works:

Good toughness

Stable wear performance

Lower cost compared to higher manganese grades

Application tips:

Suitable for aggregate and cement plants

Focus on correct mantle profile rather than extra-high manganese

Granite and Basalt (Hard and Abrasive Rock)

Granite and basalt are much harder and more abrasive than limestone, causing faster wear on standard mantles.

Recommended mantle material:

Mn18 or Mn18Cr2

Optional: TIC insert mantle for high-wear zones

Why it works:

Higher manganese content improves work-hardening

Better resistance to impact and abrasion

Application tips:

Proper feed distribution is critical

Pair with matching concave to avoid uneven wear

Iron Ore (High Hardness, High Density)

Iron ore puts heavy stress on cone crusher wear parts due to its density and compressive strength.

Recommended mantle material:

Mn18 or Mn22

TIC insert mantle for extended service life

Why it works:

Strong resistance to crushing pressure

Longer wear life under continuous heavy load

Application tips:

Monitor mantle thickness regularly

Avoid overloading to prevent premature cracking

Copper Ore and Gold Ore (Medium to Hard, Often Abrasive)

These ores vary widely depending on the mining site but are usually abrasive enough to damage low-grade mantles quickly.

Recommended mantle material:

Mn18 as a balanced choice

Mn22 for highly abrasive conditions

Why it works:

Good balance between toughness and hardness

Reliable performance across different ore grades

Application tips:

Select mantle based on actual wear feedback, not assumptions

Consistent feed size helps stabilize wear patterns

River Stone and Gravel (Hard Surface, Rounded Shape)

Although river stone looks smooth, it can be surprisingly abrasive due to silica content.

Recommended mantle material:

Mn18

TIC insert mantle for high-capacity crushing

Why it works:

Handles surface abrasion well

Maintains crushing efficiency over time

Mantle Profile Is Just as Important as Material

Besides material grade, mantle profile selection plays a key role in performance:

Short head mantles: finer output, higher wear rate

Standard mantles: balanced output and wear life

Custom profiles: optimized for specific feed conditions

Choosing the wrong profile can shorten mantle life even if the material grade is correct.

Final Advice from the Field

There is no “one-size-fits-all” cone crusher mantle. The best choice always depends on:

Ore type

Feed size and hardness

Crusher operating conditions

Desired output size

For most mining operations, working with a cone crusher mantle supplier who can recommend materials based on real application data will save more money than simply choosing the highest manganese grade.