As the global demand for mining equipment continues to rise, so does the need for high-quality replacement parts, particularly for cone crushers. One such component that has gained significant attention is the cone crusher bowl liner, a crucial part that directly impacts the efficiency and longevity of crushers in mining operations. Interestingly, cone crusher bowl liners made in China are rapidly gaining popularity worldwide. But what exactly is driving this trend? Let’s explore why these products are becoming increasingly favored in the industry.

1. Cost-Effectiveness Without Compromising Quality

One of the primary reasons for the growing demand for Chinese-made cone crusher bowl liners is their cost-effectiveness. Manufacturers in China are able to offer competitive pricing without compromising on quality. Thanks to advanced manufacturing techniques and efficient production processes, Chinese suppliers can produce high-quality liners at a fraction of the cost compared to those from other regions.

For businesses looking to lower their maintenance costs while still receiving reliable products, China-made cone crusher bowl liners are a highly attractive option.

2. High Durability and Performance

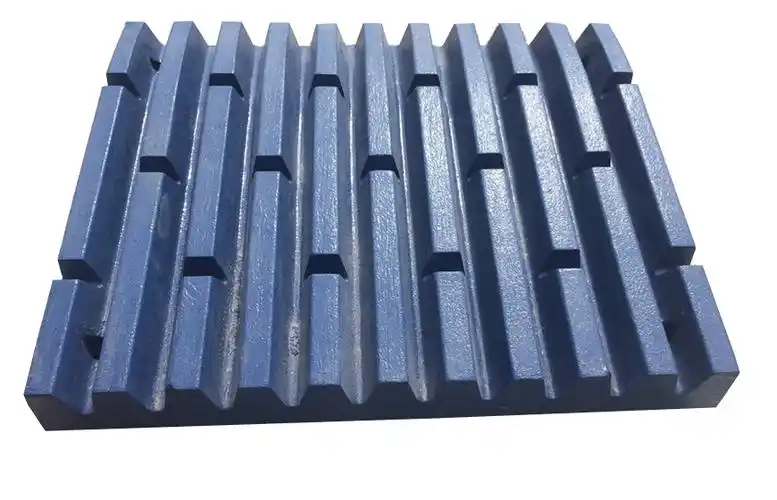

Despite being more affordable, Chinese-made bowl liners do not fall short when it comes to performance. With high-quality materials such as manganese steel and alloy, these liners are designed to withstand the harshest conditions in crushing operations.

The durability of these liners results in longer operational lifespans and fewer replacements needed, making them a smart investment for companies looking to maximize productivity while minimizing downtime.

3. Compatibility with Leading Crusher Brands

China has become a hub for producing OEM and replacement parts for major crusher brands like Metso, Sandvik, and Terex. Many Chinese manufacturers ensure that their bowl liners are compatible with a wide range of crusher models. This compatibility is a key selling point as it provides customers with seamless integration into their existing crushing setups, without the need for extensive modifications.

Whether it’s a Metso crusher or a smaller, less well-known brand, you can find Chinese-made liners that match perfectly, providing the same level of performance as OEM parts.

4. Reliable Supply and Faster Delivery Times

Another advantage is the reliable supply chain. China has a well-established manufacturing and logistics infrastructure, allowing for fast production and shipping of parts. For mining and crushing companies that require quick replacements to avoid costly downtime, Chinese suppliers can offer faster lead times compared to other regions.

The ability to provide parts quickly and efficiently is essential for companies operating in remote areas where shipping times can often be a challenge.

5. Strong Technical Expertise and Innovation

Over the years, Chinese manufacturers have invested heavily in research and development to enhance the performance and reliability of their products. As a result, they have become highly skilled in producing parts that meet both domestic and international standards.

In addition, many Chinese companies are now leading the way in technical innovation, constantly refining their processes to produce more durable and efficient bowl liners. With the implementation of modern technology, Chinese-made parts are increasingly reliable and feature advanced designs that improve crusher performance.

6. Excellent After-Sales Service

Chinese manufacturers also provide robust after-sales support for their customers, offering services such as product warranties, installation assistance, and technical support. These services help customers with the integration of the new bowl liners into their existing systems and ensure that they perform as expected.

This level of customer service further adds to the appeal of purchasing Chinese-made cone crusher bowl liners.

7. Sustainability and Environmental Considerations

Many Chinese manufacturers are now adopting eco-friendly practices in their production processes. By using sustainable materials and reducing waste, they are aligning with the growing demand for environmentally responsible products in the mining industry. As mining operations face increasing pressure to improve their environmental impact, choosing eco-conscious products like Chinese-made bowl liners can help companies meet sustainability goals.

Cone crusher bowl liners made in China offer a unique combination of quality, affordability, and performance that is increasingly attracting customers worldwide. With durable materials, compatibility with top crusher brands, fast delivery times, and strong after-sales support, these products are quickly becoming a go-to choice for businesses looking to enhance their crushing operations without breaking the bank.

As the trend of sourcing high-quality parts from China continues to grow, it’s clear that the global mining industry is recognizing the benefits of these reliable, cost-effective solutions.