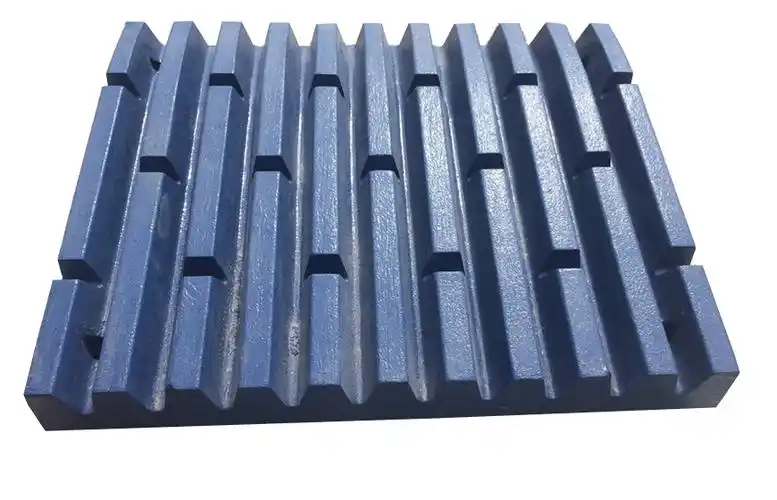

When it comes to jaw crushers, the material of the jaw plates plays a bigger role than most people realize. The right composition determines how long the plates last, how well the crusher performs, and how much downtime you can avoid. For operators working in mining, quarrying, or aggregate production, understanding the material composition of jaw plates is essential for choosing the right replacement parts.

1. High Manganese Steel (Mn13, Mn13Cr2, Mn18, Mn18Cr2)

The most common material for jaw crusher plates is high manganese steel. This alloy has a unique work-hardening ability — the harder the material hits the plate, the stronger and more wear-resistant it becomes.

Key advantages:

Excellent toughness and impact resistance

Work-hardening surface increases service life

Suitable for a wide range of stone hardness

Typical composition:

12–22% Manganese

1.5–2.2% Chromium

Balance: Iron + trace elements

2. Alloy Steel (High Chrome, Medium Carbon)

For very abrasive stone, alloy steel plates may be used. They include higher levels of chromium or other alloying elements to enhance wear resistance.

Features:

Better wear performance in highly abrasive environments

More stable hardness than manganese steel

Not as tough for continuous impact crushing

These are often preferred in industries where the feed material is extremely hard and abrasive.

3. TIC Insert Jaw Plates (Titanium Carbide Inserts)

In the last few years, TIC-insert jaw plates have become popular because they drastically extend service life. Titanium carbide rods are embedded into manganese steel, creating a hybrid structure.

Benefits:

2–4 times longer life compared to standard Mn18 plates

Reduced downtime and maintenance costs

Ideal for hard rock crushing and high-volume operations

4. Why Material Composition Matters

Each material behaves differently under strong impact, high pressure, and continuous abrasion. Choosing the wrong composition can lead to:

Early breakage

Uneven wear

Reduced output

More frequent changeouts

On the other hand, the correct plate material provides stable performance and lower operating costs.

5. How to Choose the Right Jaw Plate Material

Consider the following factors when selecting your jaw plates:

Hardness of the stone (soft, medium, hard, or extremely abrasive)

Crusher model and speed

Feed size and reduction ratio

Required output and production volume

For most applications, Mn18Cr2 is a reliable and cost-effective option. For very abrasive conditions, TIC inserts usually offer the best results.

6. About Our Replacement Jaw Plates

At Metalore, we supply high-quality replacement jaw plates compatible with major brands such as Metso, Sandvik, Terex, and others. Our plates are available in:

Mn13, Mn18, Mn22

Cr-alloy steel

TIC-insert designs for extended life

All parts follow strict chemical composition and hardness control to ensure stable performance.