In the mining and quarrying industry, jaw crushers are among the most critical pieces of equipment. They are widely used for primary crushing of hard rocks and ores, ensuring that material is processed efficiently before entering secondary crushing stages. One of the most important components of a jaw crusher is the jaw plate, also known as the fixed and movable plates, which are in direct contact with the materials being crushed. Over time, these plates experience wear, which affects crushing efficiency, maintenance costs, and the overall productivity of mining operations.

At Metalore, we specialize in providing high-quality crusher spare parts, including jaw plates, mantles, concaves, blow bars, and other wear parts compatible with major brands like Metso, Sandvik, Trio, Terex, and more. Understanding the wear mechanisms and optimizing the life of jaw plates is critical for mining companies to reduce downtime and operating costs.

1. Common Causes of Jaw Plate Wear

Jaw plate wear is influenced by multiple factors, ranging from the type of material processed to operational settings and maintenance practices. The following are the most common causes:

1.1 Material Hardness and Abrasion

The hardness of the crushed material significantly affects jaw plate wear. High-abrasion rocks, such as granite or quartz, will wear down jaw plates faster than softer stones like limestone. Additionally, the presence of sand or other abrasive particles in the feed can accelerate the wear process.

1.2 Improper Feeding

Uniform feeding is crucial. Oversized rocks, uneven distribution, or feeding from a single side can create high-stress points on jaw plates, causing localized wear or even cracks. Using a feeder to regulate material flow and avoid overloading is recommended.

1.3 Operational Parameters

Incorrect settings, such as inappropriate closed side setting (CSS), crusher speed, or excessive load, can lead to inefficient crushing and accelerated wear. Overfeeding or operating at higher-than-recommended speeds increases stress on the jaw plates.

1.4 Maintenance Practices

Neglecting routine inspections and delayed replacement of worn plates can exacerbate wear issues. Cracks, chipping, and uneven surfaces reduce crushing efficiency and may lead to equipment failure.

2. How to Optimize Jaw Plate Life

Extending jaw plate life involves selecting the right material, optimizing operational parameters, and implementing a proactive maintenance strategy.

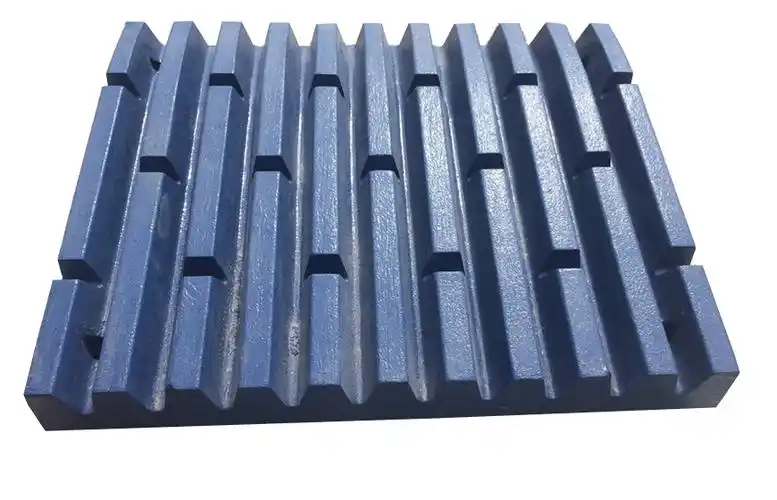

2.1 Material Selection

High manganese steel is the most commonly used material for jaw plates due to its excellent impact resistance and work-hardening properties. In certain applications, alloy steel or heat-treated cast steel may be preferred to balance cost and durability. Choosing the correct material based on ore hardness and abrasiveness is essential.

2.2 Proper Crusher Settings

Closed Side Setting (CSS): Maintaining the correct gap between the fixed and movable plates ensures proper crushing and reduces unnecessary stress.

Crusher Speed: Operating within manufacturer-recommended RPM prevents excessive force on the plates.

Feed Size Control: Avoid oversized materials that can cause localized wear or damage.

2.3 Regular Inspections and Maintenance

Inspect jaw plates for cracks, wear patterns, and chipping regularly.

Rotate or reverse plates to ensure even wear when applicable.

Replace plates before excessive wear affects crushing efficiency.

2.4 Uniform Feeding and Load Management

Use feeders or conveyors to ensure uniform material distribution.

Avoid sudden spikes in load, which can create stress points.

Proper material gradation also helps reduce wear on jaw plates.

3. Signs of Jaw Plate Wear

Recognizing wear signs early can prevent unplanned downtime. Common indicators include:

Decreased crushing efficiency: Larger product size than usual.

Excessive vibration or noise: Indicating uneven plate wear or loose components.

Visible cracks or chips: Immediate replacement may be required.

Increased energy consumption: Crusher works harder to achieve the same output.

4. Benefits of Optimizing Jaw Plate Life

Investing in proper maintenance and high-quality jaw plates brings tangible benefits:

Reduced downtime: Fewer unplanned stoppages due to worn plates.

Lower operating costs: Longer-lasting plates reduce replacement frequency.

Improved production efficiency: Consistent crushing output with minimal waste.

Better product quality: Uniform particle size from well-maintained plates.

At Metalore, our high-quality jaw plates and other crusher spare parts are designed for optimal performance, helping mining operations maintain productivity while reducing costs.

5. Choosing the Right Jaw Plate Supplier

Selecting a reliable supplier is just as important as choosing the right material. Key considerations:

Compatibility with major brands: Metso, Sandvik, Trio, Terex.

Quality assurance: High hardness, wear resistance, and dimensional accuracy.

Customization capabilities: OEM or custom manufacturing based on part numbers or drawings.

Delivery and support: Fast delivery and technical support for installation and maintenance.

Metalore provides comprehensive solutions for mining and quarry operators, including jaw crushers, cone crushers, impact crushers, and all associated wear parts. Our team ensures that every part meets strict quality standards, allowing clients to minimize downtime and maintain production efficiency.

6. Practical Tips for Mining Operations

Track wear patterns: Document which parts wear faster and why.

Rotate plates when possible: Extend overall lifespan.

Maintain proper lubrication and alignment: Reduce stress and wear.

Train operators: Proper operation reduces unnecessary wear.

Plan replacements proactively: Avoid emergency stoppages.

Optimizing jaw plate life is crucial for any mining equipment operation. By understanding the causes of wear, selecting the right material, and maintaining proper operational practices, mining companies can significantly reduce costs and improve productivity.

High-quality jaw plates and crusher spare parts from Metalore provide a reliable solution for mining, quarrying, and aggregate operations worldwide. Whether you are using Metso, Sandvik, Trio, or Terex crushers, Metalore ensures that your equipment performs efficiently and consistently.