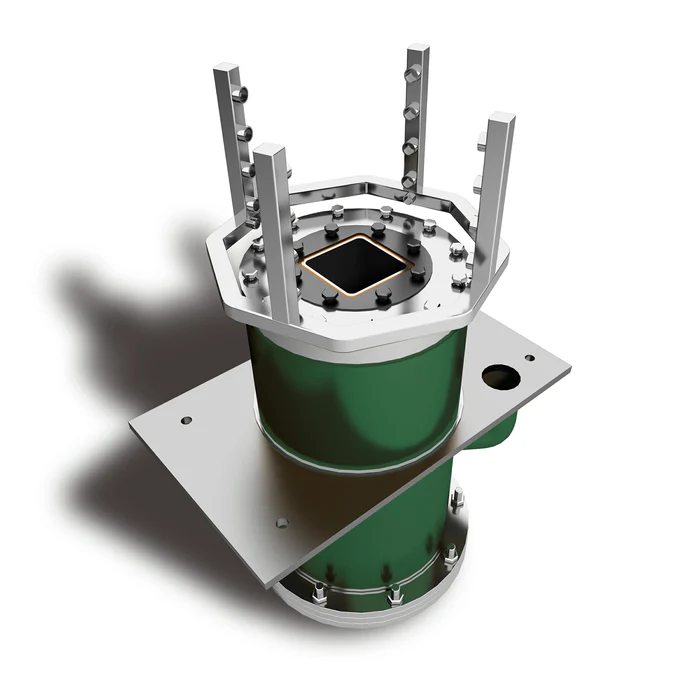

The CCM Crystallizer Aggregate is a critical component in continuous casting machines, designed to facilitate the solidification and shaping of molten metal as it is poured into molds. This aggregate consists of various high-performance components, including cooling systems, mold liners, and guiding devices, all engineered to ensure the efficient and uniform cooling of molten steel. The crystallizer components are designed to handle extreme temperatures and mechanical stresses during the casting process, ensuring high-quality steel production with minimal defects. Available in customizable configurations, the CCM Crystallizer Aggregate is essential for maintaining the integrity of the casting process and improving overall production efficiency.

Key Features:

High-Performance Components: Includes cooling systems, mold liners, and guiding devices, designed for optimal performance.

Temperature Resistance: Manufactured to withstand extreme temperatures during the solidification of molten steel, ensuring reliable operation.

Precision Engineering: Designed with precision to maintain uniform cooling and solidification for high-quality output.

Durable and Reliable: Built to endure the mechanical stresses of continuous casting, reducing maintenance needs and downtime.

Customizable: Available in various configurations to meet specific production requirements and fit different CCM systems.

Applications:

The CCM Crystallizer Aggregate is used in continuous casting systems in steelmaking plants, playing a key role in the production of high-quality steel products such as billets, blooms, and slabs. It is essential for ensuring efficient and reliable solidification during the casting process.