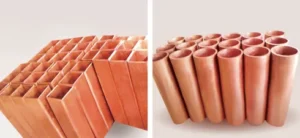

Copper Mould Tubes (also known as Copper Mold Tubes) are essential components in continuous casting machines, widely used in the steel industry for casting various shapes of steel products such as billets, blooms, and slabs. Made from high-quality copper alloys, these mould / mold tubes provide excellent thermal conductivity, ensuring uniform solidification of molten metal and maintaining the integrity of the casting process.

Advantages:

Technical Parameters:

Thickness of the tubes: 10–35 mm

Material:

Phosphorized copper (TP2), Cu-Ag, CuCrZr

Coating options:

Cr, Cr-Ni (Ni-Co-Fe), Ni-Co, Co-Ni

Taper types:

Single taper, multi-taper, parabolic taper, compound taper, diamond taper, etc.

Specifications:

Square billet: 60×60 – 700×700 mm

Rectangular billet: 120×340 – 365×700 mm

Round billet: Ø90 – 800 mm

Length: 700–1000 mm

Key Features:

Superior Thermal Conductivity

Copper mould / mold tubes offer excellent heat transfer performance, promoting rapid and uniform solidification and minimizing common casting defects.

Durability and Wear Resistance

Engineered to withstand high thermal and mechanical stresses during continuous casting, ensuring a longer service life for both copper mould tubes and copper mold tubes.

Precise Dimensions

Manufactured with strict dimensional tolerances to ensure accurate fit and reliable performance in continuous casting operations.

Customizable Designs

Our copper mould tubes (copper mold tubes) are available in various sizes, tapers, and coatings to meet specific customer requirements and compatibility with different casting machines.

Corrosion and Oxidation Resistance

Copper’s natural resistance to corrosion and oxidation ensures stable performance of the copper mold tube in harsh molten metal environments.

Applications:

Copper mould tubes, also referred to as copper mold tubes, play a critical role in the production of high-quality steel by ensuring smooth casting and reducing cracks or surface defects. They are widely used in continuous casting processes for billets, blooms, bars, and slabs.

This high-performance Copper Mould / Mold Tube ensures optimal casting quality and production efficiency, making it a trusted choice for steel manufacturers worldwide.

FAQs

Q1: Is your copper mould tube compatible with our existing copper mold tube?

A: Yes. Our copper mould tubes are manufactured as direct replacements for existing copper mold tubes. As long as the drawing, dimensions, and casting machine model are confirmed, they can be installed without modifying your mould assembly.

Q2: Can your copper mold tube replace JSM / Danieli / SMS mould tubes directly?

A: Yes. We supply copper mould tubes that are fully compatible with JSM, Danieli, SMS, and other continuous casting machines. Many customers use our copper mold tubes as cost-effective replacements for original mould tubes.

Q3: What information do you need before quoting a copper mould / mold tube?

A: For accurate pricing, we usually need the mould tube drawing, cross-section size, length, steel grade, coating requirement, and annual consumption. With this information, we can quote the copper mould tube or copper mold tube quickly.

Q4: How does the price compare with original copper mold tubes?

A: Our copper mould tubes are typically 30–50% lower in cost compared with original brand copper mold tubes, while meeting the same functional and installation requirements.

Q5: What is the typical delivery time for copper mould tubes?

A: Standard copper mould tubes usually take 3–5 weeks for production. For customized copper mold tubes based on drawings, delivery time depends on complexity and order quantity.

Q6: What material and coating do you use for copper mold tubes?

A: We use CuCrZr copper with optional hard chromium plating or customized coatings. The same material standards apply to both copper mould tubes and copper mold tubes supplied to different markets.

Q7: Have your copper mould tubes been used by steel plants before?

A: Yes. Our copper mould tubes have been supplied to steel plants and rolling mills in India, the Middle East, and Africa as replacement copper mold tubes for continuous casting machines.

Q8: What is the service life of your copper mold tube in actual use?

A: Service life depends on casting speed, steel grade, and cooling conditions. In comparable operating conditions, our copper mould tubes deliver stable performance similar to original copper mold tubes.

Q9: Can you supply small quantities or trial orders for copper mould tubes?

A: Yes. Trial orders are accepted so customers can evaluate our copper mould tubes or copper mold tubes before placing repeat or bulk orders.

Q10: How do you ensure the quality of copper mould / mold tubes before shipment?

A: Each copper mould tube is inspected for dimensions, surface finish, coating thickness, and material composition before shipment to ensure it meets customer requirements.