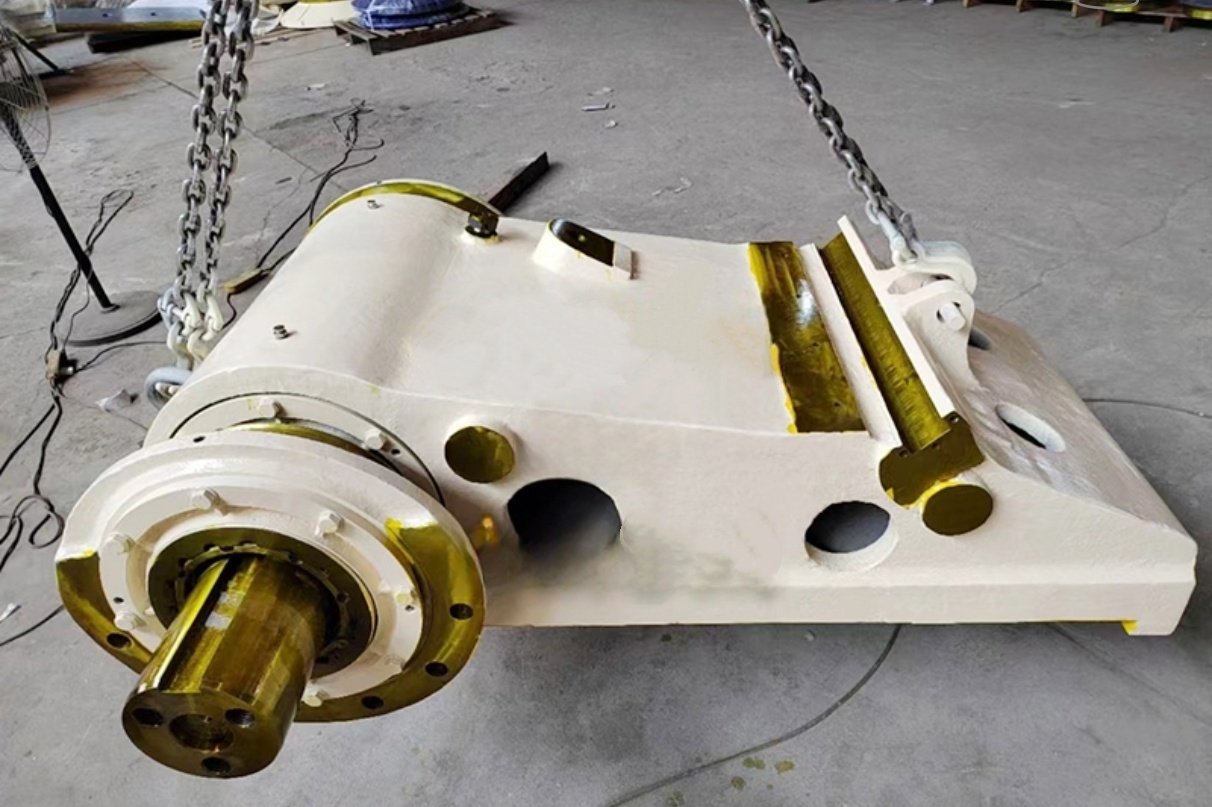

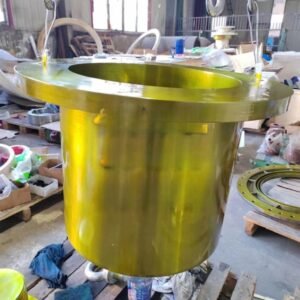

The jaw crusher pitman is one of the key load-bearing components of the crusher, responsible for converting the rotary motion of the eccentric shaft into the crushing movement of the movable jaw. As a critical structural part operating under high impact, vibration, and heavy working conditions, the pitman must deliver exceptional mechanical strength, stability, and fatigue resistance.

Metalore supplies high-strength forged and cast pitmans that meet or exceed OEM standards, compatible with a wide range of internationally recognized brands such as Metso, Sandvik, FLSmidth, Terex, Telsmith, and other equivalent mining and quarrying machines. Our pitmans are precision-machined to ensure proper alignment with bearings, toggle systems, and jaw assemblies, delivering reliable performance even in the toughest environments.

Each unit undergoes strict quality inspection—including chemical composition analysis, hardness testing, and flaw detection—to guarantee durability, long service life, and secure operation of your jaw crusher.

Key Features

High Structural Strength

Manufactured from premium alloy or manganese steel with strong load-bearing capacity and excellent resistance to cracking and fatigue.OEM-Standard Machining

Machined to precise tolerances for secure fitment with bearings, toggle assemblies, and the crusher frame.Wide Compatibility

Designed for use in a variety of jaw crusher models from leading brands, supporting direct interchange with OEM parts.Improved Wear & Impact Resistance

Heat treatment and optimized material formulation ensure stable long-term performance in continuous crushing applications.Quality Inspection Before Delivery

Every pitman is tested for hardness, dimensional accuracy, material quality, and internal defects to ensure long service life.

Applications

Mining

Quarrying

Aggregate production

Cement and construction materials

Metallurgical ore processing

Suitable for primary and secondary crushing in industries requiring continuous operation and high throughput.

Options

Alloy steel / high-manganese steel / customized materials

OEM standard or upgraded reinforced versions

Precision machining with tolerance control

Custom manufacturing from drawings or samples

Why Choose Us

Professional aftermarket supplier with global reputation

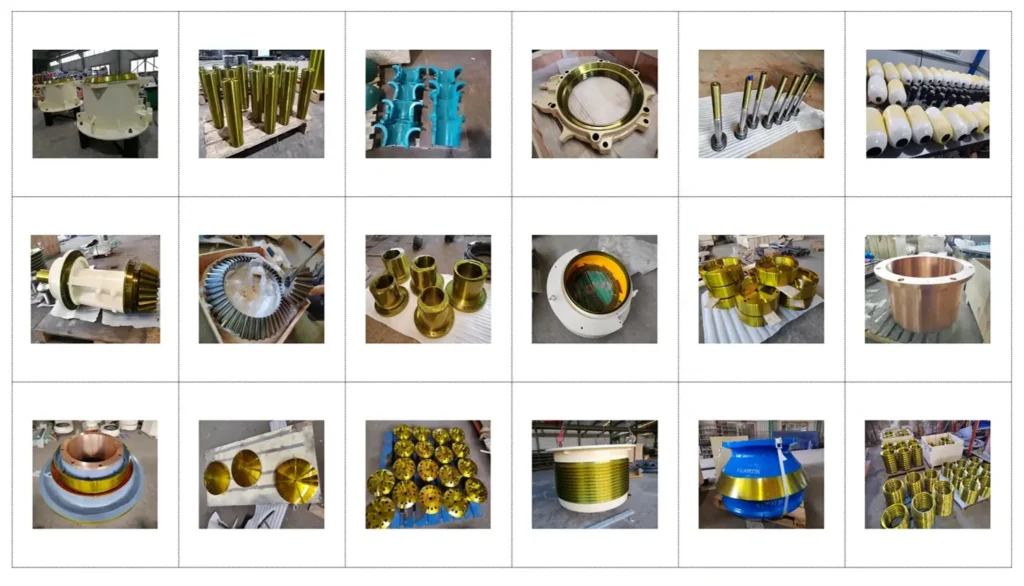

Able to supply jaw plates, pitmans, bearings, flywheels, toggle plates, side plates, and other wear and structural parts

Fast delivery and stable quality for long-term operations

Dedicated support for model selection and customization

We provide all crusher spare parts, including but not limited to the following items