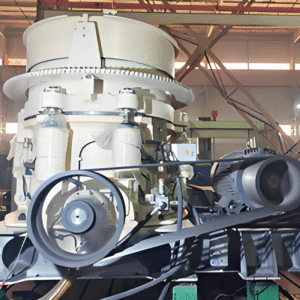

The jaw crusher is designed for coarse and medium crushing of hard, abrasive ores and rocks. It features a detachable, weld-free frame, an optimized crushing chamber design, a double-wedge adjustment mechanism, high-quality raw materials and components, an elastic limit shock absorption system, and an integrated motor base. These thoughtful design elements ensure high crushing efficiency, low investment cost, long service life, and stable operation.

Working Principle

The upper end of the moving jaw is directly suspended on the eccentric main shaft, acting as a crank linkage. The eccentric shaft drives the movement, while the lower end of the moving jaw is connected to the toggle plate, which is supported at the rear of the frame. As the eccentric shaft rotates, the trajectory of points on the moving jaw transitions from a circular path at the suspension point to an increasingly elliptical motion toward the bottom. The lowest part of the jaw follows a curved path connecting with the thrust plate.

Key Advantages

Low noise and minimal dust emissions.

High crushing ratio and uniform product size.

Simple structure, reliable operation, and low operating costs.

Easy replacement of parts and straightforward maintenance.

Deep crushing chamber with no dead zones, improving feed capacity and output.

Energy-efficient: consumes 15–30% less power compared to older models.

Wide range of discharge opening adjustment to meet various operational requirements.

Structural Advantages

Optimized Crushing ChamberThrough careful optimization of the chamber structure and the moving jaw’s motion trajectory, the crusher achieves a balanced moment of inertia and a longer stroke, resulting in higher crushing efficiency at the same energy consumption.

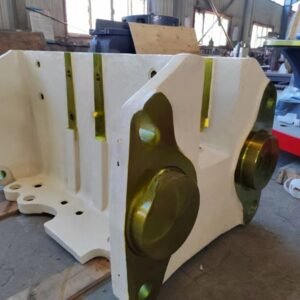

Detachable Weld-Free Frame

Avoids stress concentration issues caused by welding and provides a more compact and reliable structure. Major damaged components can be replaced, significantly extending service life and reducing costs for customers.

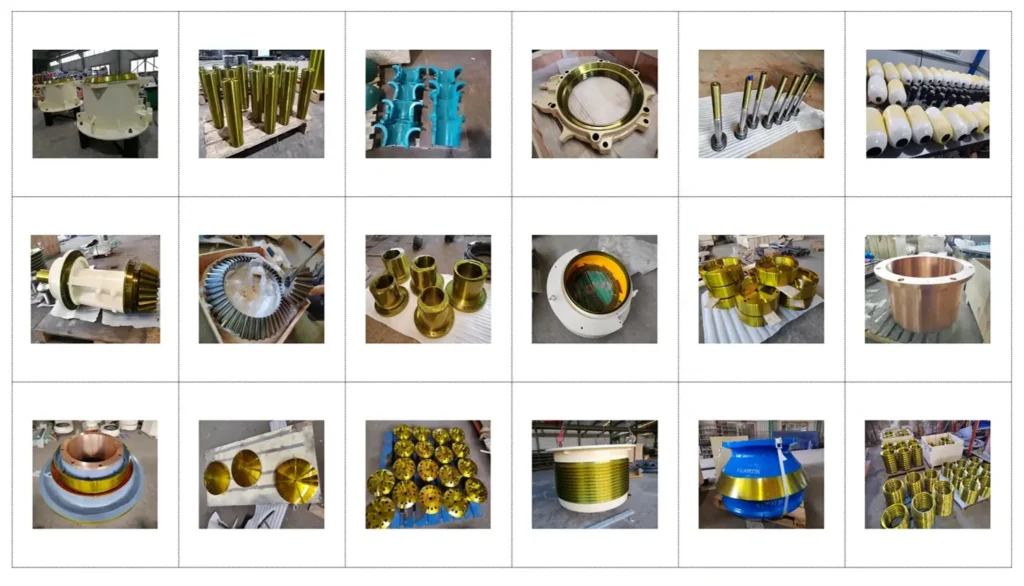

High-Quality Materials and Components

All major castings and forgings are precision inspected to ensure quality. Motors, bearings, and other critical components are sourced from reputable brands.

Integrated Motor Base

The integrated motor base is securely mounted on the crusher, reducing installation space requirements and providing a more stable driving force.

Elastic Limit Shock Absorption System

The combination of elastic limit blocks and rubber shock absorbers effectively absorbs peak vibration loads, minimizing impact between the crusher and its foundation, thereby extending service life.

Double-Wedge Adjustment Mechanism

Replaces the traditional shim-type discharge opening adjustment, making it simpler and more convenient to set the desired output size.