Product Name: Jaw Crusher Toggle Plate – Aftermarket Replacement

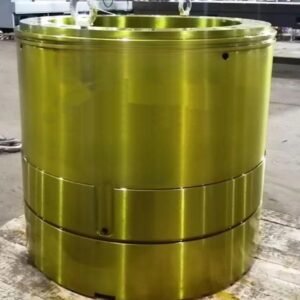

Material: High-strength manganese steel / Alloy steel / Custom materials available

Function:

The toggle plate is a critical component of a jaw crusher, serving as a safety and tensioning mechanism. It connects the movable jaw and the pitman, transferring force while protecting the crusher from overload. In case of uncrushable material, the toggle plate will break to prevent damage to the main frame and other critical parts, acting as a “safety fuse” for your equipment.

Compatibility:

Compatible with a wide range of jaw crushers from leading international brands, including Metso, Sandvik, FLSmidth, Terex, Telsmith, Nordberg, and other equivalent models.

Quality Control:

Each toggle plate undergoes strict inspection including chemical composition analysis, hardness testing, and dimensional verification to ensure proper fit, safety, and long service life.

Applications:

Mining

Quarrying

Aggregate processing

Cement and construction

Metallurgical operations

MOQ: 1 piece

Lead Time: 7–15 working days depending on stock

Payment Terms: T/T, L/C, and other common international payment methods

Warranty: 12 months (subject to working conditions)

Key Features

High Strength & Safety: Designed to withstand heavy loads and act as a protective “safety fuse” under overload conditions.

OEM-Standard Fit: Machined to precise tolerances for correct alignment with pitman and movable jaw.

Wide Compatibility: Suitable for most major jaw crusher brands and equivalent models.

Durable Materials: Made of high-strength manganese or alloy steel to ensure long-term operation.

Strict Quality Inspection: Ensures proper fit, durability, and safe performance.

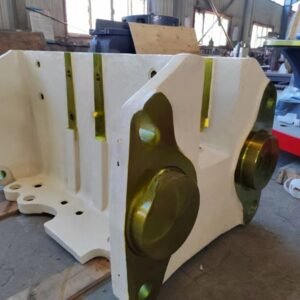

Metalore is a professional supplier of aftermarket crusher wear parts. We offer a full range of jaw plates, pitmans, toggle plates, side plates, flywheels, cone crusher mantles, hammers, and other replacement parts for globally recognized mining and quarrying equipment.

Whether you need a single toggle plate or a complete set of replacement parts, we provide OEM-standard quality, fast delivery, and long-lasting solutions.

We provide all crusher spare parts, including but not limited to the following items