Product Advantages

Equipment Introduction

The MGP series single-cylinder cone crusher features a high crushing ratio, excellent product quality, and stable operation. It is versatile and suitable for various working conditions and materials, meeting the requirements for medium, fine, and ultra-fine crushing. For river pebble crushing, it can even be used directly for coarse crushing.

Optimized Structure for Higher Efficiency

The main shaft is supported at both ends, allowing it to withstand greater crushing forces and stroke. The optimized liner selection ensures higher crushing efficiency and stable operation.

Working Principle

The eccentrically swinging moving cone compresses the material entering from the feed hopper within the fixed crushing cavity to complete the crushing process.

Hydraulic control allows adjustment of the discharge opening and provides overload protection.

By changing the liner configuration, a wider range of discharge sizes can be achieved using the same main machine.

Applicable Materials and Uses

Suitable for metal materials such as iron, copper, gold, manganese, molybdenum, lead, and aluminum;

And for non-metallic materials such as granite, limestone, dolomite, basalt, river pebble, calcite, barite, calcium carbonate, and coal gangue.

Enhanced Automation

The PLC control system can independently control a single unit according to production requirements, or be integrated into a complete production line for centralized automated control.

Easy Operation and Maintenance

The intuitive interface makes operation simple and user-friendly. Hydraulic control allows stepless adjustment of the discharge opening, reducing downtime.

Parameters

Performance Parameters (Fine Crushing) Table

Model | Crushing Chamber Type | Eccentricity (mm) | Feed Opening (mm) | Capacity (t/h) | Motor Power (kW) |

MGP100 | C (Coarse) | 16-25 | 142 | 35-102 | 75-90 |

M (Medium) | 141 |

MF (Medium Fine) | 95 |

F (Fine) | 53 |

EF (Extra Fine) | 46 |

EC (Extra Coarse) | 213 |

MGP200 | C (Coarse) | 18-40 | 182 | 70-275 | 132-220 |

M (Medium) | 118 |

MF (Medium Fine) | 101 |

F (Fine) | 89 |

EF (Extra Fine) | 58 |

Performance Parameters (Medium Crushing) Table

Model | Crushing Chamber Type | Eccentricity (mm) | Feed Opening (mm) | Capacity (t/h) | Motor Power (kW) |

MGP100S | C (Coarse) | 16-25 | 239 | 80-245 | 75-90 |

M (Medium) | 206 |

MGP200S | EC (Extra Coarse) | 18-36 | 295 | 110-362 | 110-160 |

C (Coarse) | 222 |

MGP300 | EC (Extra Coarse) | 18-40 | 225 | 105-388 | 250-315 |

C (Coarse) | 184 |

M (Medium) | 135 |

MF (Medium Fine) | 107 |

F (Fine) | 85 |

EF (Extra Fine) | 55 |

MGP5000 | EC (Extra Coarse) | 25-45 | 250 | 140-505 | 250-400 |

C (Coarse) | 192 |

M (Medium) | 152 |

MF (Medium Fine) | 113 |

F (Fine) | 95 |

EF (Extra Fine) | 68 |

MGP300S | EC (Extra Coarse) | 18-36 | 332 | 180-436 | 132-250 |

C (Coarse) | 247 |

MGP500S | EC (Extra Coarse) | 18-40 | 401 | 300-878 | 200-355 |

C (Coarse) | 321 |

FAQs

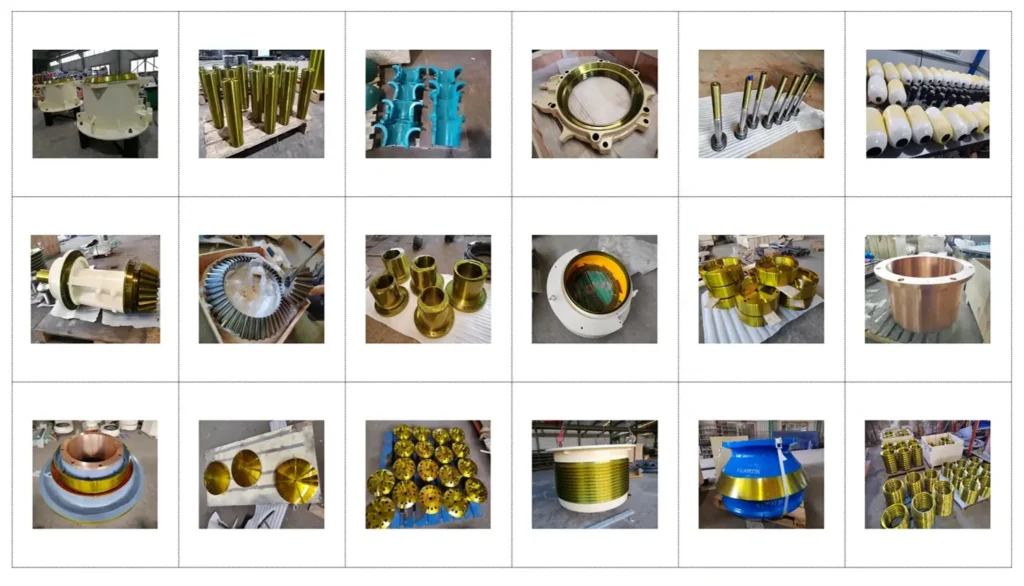

Q1: Are you a trading company or a manufacturer?

A: Metalore is a professional manufacturer. We specialize in crusher spare parts and metallurgical equipment. Our products are exported worldwide and trusted by customers in multiple countries. We focus on providing high-quality replacement parts for internationally renowned brands such as Metso, Sandvik, Terex, and offering reliable alternatives at competitive prices without compromising performance.

Q2: Do you accept customization?

A: Yes, we offer customization. You need to provide drawings or technical requirements, and our engineering team will produce according to your specifications. You can also provide the part numbers for the original equipment (Metso and Sandvik).

Q3: What are your service and payment terms?

A: We accept T/T and L/C. Standard terms are 30% deposit in advance, 70% balance before delivery, which is common in international trade. We will provide product photos for your confirmation before shipment to ensure accuracy and quality.

Q4: Do you provide technical support or installation guidance?

A: Yes, we offer professional technical support, including product selection guidance, installation instructions, and troubleshooting assistance.

Q5: Can Metalore products replace original brand parts directly?

A: Yes, our replacement parts are designed to be fully compatible with original brand equipment, offering reliable alternatives that meet or exceed OEM standards.

Q6: How do you ensure product quality?

A: Our products come with a one-year warranty and undergo physical and chemical testing before leaving the factory, including spectrometer analysis, flaw detection, hardness testing, and other relevant tests.