Product Advantages

High Performance

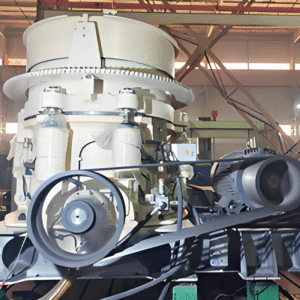

The combination of a heavy-duty rotor design, high wear-resistant materials, and optimized crushing chamber design enhances capacity and product quality while reducing production costs and wear part consumption.

The precisely engineered and securely mounted blow bars eliminate stress concentration, reduce the risk of bar breakage, and improve safety and reliability.

Low Operating Cost

The rotor’s large rotational inertia increases output and saves energy.

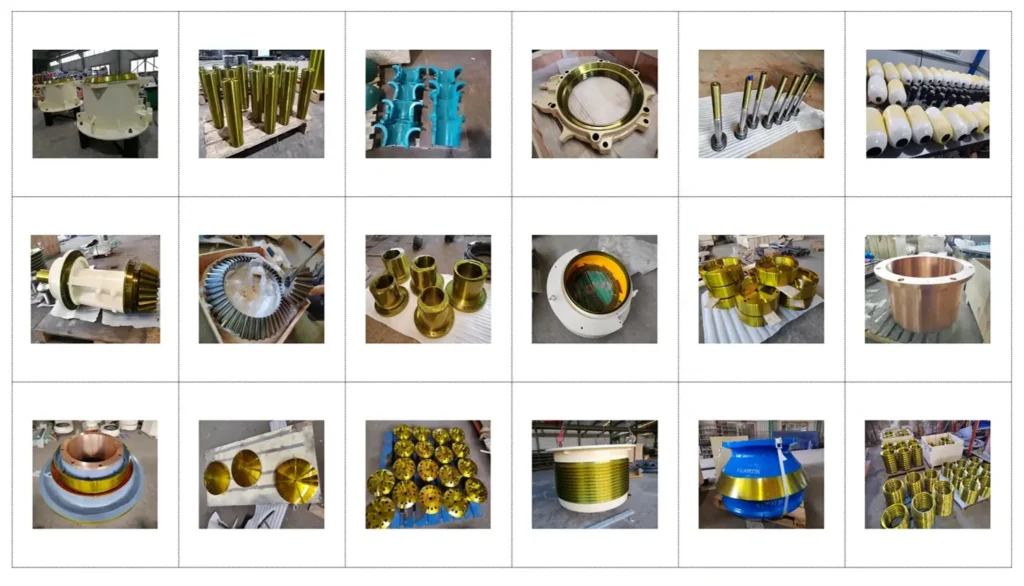

Wear parts with different levels of wear can be interchanged, reducing the number of spare parts required.

High Versatility and Flexible Configuration

Applicable to various crushing stages and recycling processes.

The equipment can be configured with different optional components to meet specific application needs.

Easy Maintenance

The hydraulic system allows convenient discharge opening adjustment and enables the crusher frame to be opened for easier internal inspection and maintenance.

Blow bars can be replaced from either direction, making it suitable for confined and complex work environments.

An optional rotor positioning system is available, allowing safe and accurate rotor positioning for blow bar replacement or discharge adjustment without entering the crusher.