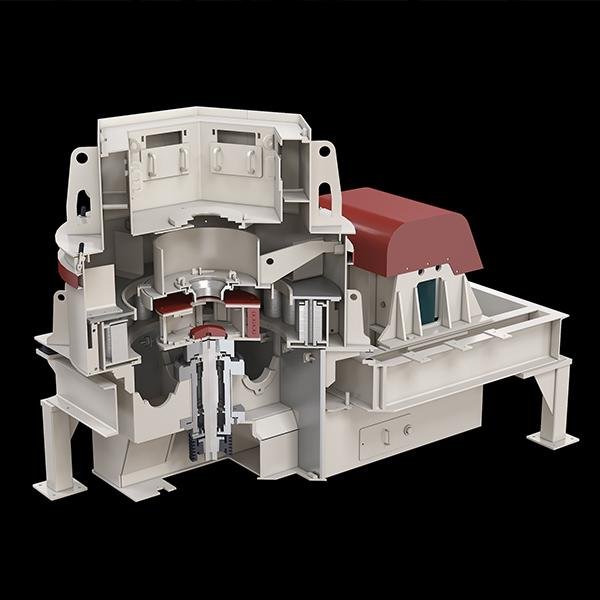

Vertical Shaft Impact Crusher (VSI Crusher) is a high-efficiency sand-making and fine-crushing machine widely used in mining, quarrying, aggregate production, and construction industries. It operates by accelerating materials through a high-speed rotor and crushing them through impact with wear-resistant anvils or rock-on-rock chambers. This technology delivers excellent shaping performance and consistent product gradation.

Key Features

High Sand-Making Efficiency

Produces high-quality, cubical-shaped aggregates suitable for concrete, asphalt, and road base applications.Advanced Rotor Technology

High-speed rotor ensures strong crushing force and stable output. Rotor tips and wear plates are designed for maximum durability.Multiple Crushing Modes

Supports rock-on-rock and rock-on-steel crushing, adaptable for different materials and application requirements.Low Operating Cost

Optimized chamber structure reduces wear consumption and improves energy efficiency.Easy Maintenance

Simple opening mechanism, easy access to wear parts such as rotor tips, distributor plate, feed tube, and wear liners.Wide Application Range

Suitable for basalt, granite, limestone, river stone, quartz, slag, and other hard/abrasive materials.

Working Principle

Material enters the crusher through the feed tube and is accelerated by the rotor to high velocity. The material is then projected into the crushing chamber, colliding with other stones or impact plates, resulting in efficient fine crushing and excellent particle shaping.

Typical Output Sizes

0–5 mm manufactured sand

5–10 mm fine aggregates

(Custom gradation available based on rotor configuration and speed.)

Applications

Manufactured sand production

Aggregate shaping

Mining & quarrying

Concrete & asphalt plants

Metallurgical slag crushing

High-grade highway & railway projects

Available Models

We supply VSI crushers in various capacities from 50–500 TPH, suitable for small, medium, and large production lines. Custom rotor designs and chamber configurations are available.

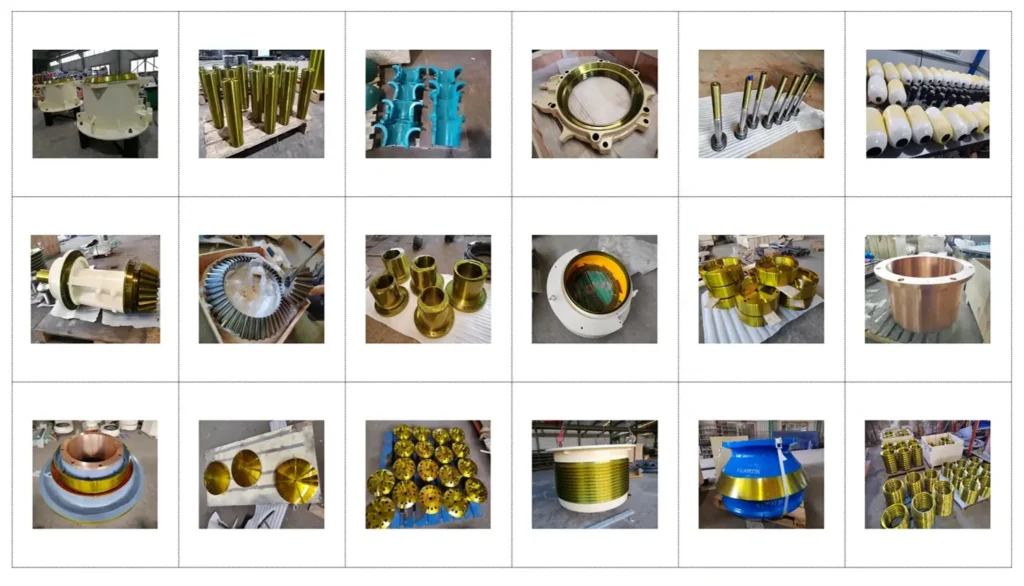

Wear Parts Supply

Compatible replacement parts are available, including:

Rotor tips

Distributor plate

Anvils

Wear plates

Feed tube

Upper & lower liners

High-chromium and carbide materials ensure long wear life.