Buying the right crusher spare parts is essential to keep your equipment running efficiently and to minimize downtime. However, many operators make common mistakes that can lead to higher costs, frequent breakdowns, and reduced crusher life. Here are the top mistakes and tips on how to avoid them.

1. Not Knowing the Exact Part Number

One of the most common errors is ordering without the correct OEM part number. Crusher models often have multiple versions, and even small differences in size or design can make a part incompatible.

How to avoid it:

Always check the casting number or part number on the existing component.

If uncertain, consult the manufacturer’s manual or a trusted supplier to verify compatibility.

2. Choosing the Cheapest Option

Focusing solely on price can be risky. Low-cost parts may wear faster or fail under heavy use, leading to more frequent replacements and potential damage to other components.

How to avoid it:

Consider the total cost of ownership, not just the upfront price.

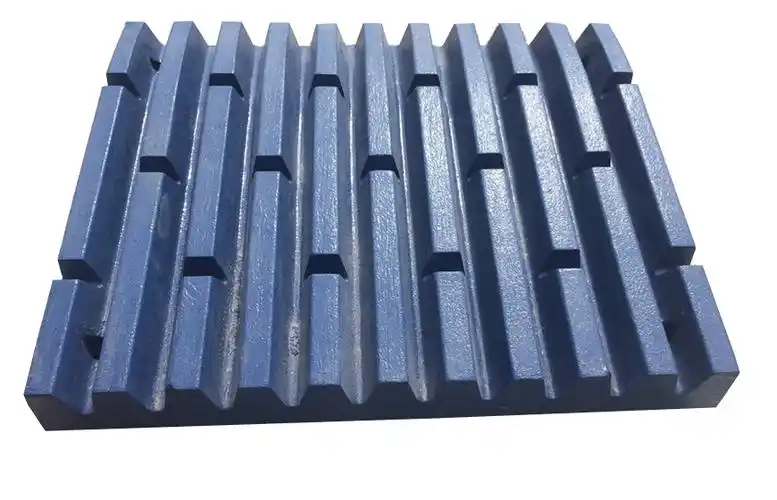

Choose replacement parts made from high-quality materials like high manganese steel for jaws, mantles, and concaves.

Work with reputable suppliers who can guarantee durability and compatibility.

3. Ignoring Material and Hardness Requirements

Different rocks have varying hardness and abrasiveness. Using parts not designed for your application can lead to rapid wear.

How to avoid it:

Identify the type of rock your crusher handles (soft, medium, hard).

Select parts designed for that material, such as Mn14–Mn22 manganese steel for abrasive rocks.

Adjust part thickness or alloy content based on operating conditions.

4. Failing to Consider Crusher Model and Stage

Using the wrong part for your crusher type or crushing stage can reduce efficiency and increase wear. For example, parts for a primary jaw crusher differ from those for a cone crusher or secondary impact crusher.

How to avoid it:

Know your crusher model, stage, and intended product size.

Match replacement parts (jaw plates, mantles, concaves, blow bars) to the crusher’s specifications.

5. Buying from Unverified Suppliers

Purchasing from unreliable sources may result in counterfeit or low-quality parts. This can damage your crusher, cause downtime, and void warranties.

How to avoid it:

Choose trusted suppliers with industry experience.

Ensure the supplier provides detailed specifications, material certificates, and OEM compatibility.

For brands like Metso, Sandvik, Terex, check if the parts are precision-engineered replacements.

6. Overlooking Maintenance and Installation

Even high-quality parts can fail prematurely if not installed or maintained correctly. Poor installation can lead to misalignment, uneven wear, and machine damage.

How to avoid it:

Follow manufacturer guidelines for installation.

Train staff on proper maintenance practices.

Schedule regular inspections and replace parts before severe wear occurs.

Conclusion

Avoiding these common mistakes when buying crusher spare parts can save you money, reduce downtime, and extend the life of your equipment. Always verify part numbers, choose quality materials, match parts to your crusher and rock type, and work with trusted suppliers.